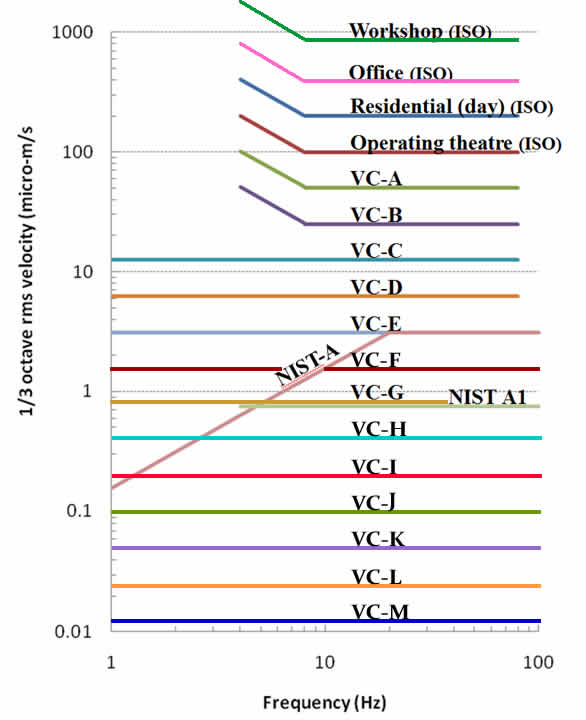

Vibration Criterion (VC) Curves

The VC (Vibration Criteria) curves were developed in the early 1980s by Eric Ungar and Colin Gordon. They were originally developed as a generic vibration criteria for vibration-sensitive equipment for use in the semiconductor, medical and biopharmaceutical industries, but have found application in a wide variety of technological applications.

The criteria takes the form of a set of one-third octave band velocity spectra, together with the International Standards Organization (ISO) guidelines for the effects of vibration on people in buildings. The criteria apply to vibration as measured in the vertical and two horizontal directions.

The NIST-A criterion was developed for metrology, but has gained popularity within the nanotechnology community. The NIST-A criterion is a very difficult criterion to meet at some sites with significant low-frequency vibrations.

The VC curves are now widely accepted throughout the world as a basis for designing a facility to meet the requirements of a group of highly vibration sensitive equipment used close together.

University of Michigans Ultra-Low Vibration Lab (ULVL) was completed in 2014. After the construction, a vibration survey was done on the Ultra-Low Vibration Lab chambers. The measurements demonstrated that even when a single vehicle was driving on a nearby street, the vibrations exceeded the NIST-A specifications necessary for the ULVL.

The University of Michigan ordered seven customized tabletops and 31 custom Minus K Negative-Stiffness vibration isolators with pedestals provided for the eight Ultra-Low Vibration Lab chambers.

Customized Minus K Technology Negative-Stiffness vibration isolation table installed in one of the Ultra-Low Vibration Lab chambers

The final vibration survey by Colin Gordon Associates (CGA), after installation of the customized Minus K Negative-Stiffness isolators and tables, showed the measured vibration levels in all ULVL chambers from VC-K to VC-M at frequencies above 2.5 Hz, well below the NIST-A Vibration Criterion required.

"VC-M is the lowest we have ever measured, though we werent able to measure below 2.5 Hz because our most sensitive sensor wont go lower, due to sensor noise floor," said Hal Amick, Vice President of Colin Gordon Associates.

The updated VC Curve(shown above) shows these lower curve levels that were measured by CGA and have already assisted University of Michigans ULVL with two major scientific milestones.

Vibration site surveys can tell you a lot about how to specify equipment for vibration isolation in your laboratory.

| Curve Criterion | Velocity1 μm/s (μin/s) |

Detail Size2 |

Description of Use |

| Workshop (ISO) | 800( 32,000) |

N/A |

Distinctly perceptible vibration. Appropriate to workshops and non-sensitive areas. |

| Office (ISO) | 400 (16,000) |

N/A |

Perceptible vibration. Appropriate to offices and non-sensitive areas |

| Residential Day (ISO) | 200 (8000) |

75 |

Barely perceptible vibration. Appropriate to sleep areas in most instances. Usually adequate for computer equipment, hospital recovery rooms, semiconductor probe test equipment and microscopes less than 40x. |

| Op. Theatre (ISO) | 100 (4000) |

25 |

Vibration not perceptible. Suitable in most instances for surgical suites, microscopes to 100X and for other equipment of low sensitivity. |

| VC-A | 50 (2000) |

8 |

Adequate in most instances for optical microscopes to 400X, microbalances, optical balances, proximity and projection aligners, etc. |

| VC-B | 25 (1000) |

3 |

Appropriate for inspection and lithography (including steppers) to 3 μm line widths.. |

| VC-C | 12.5 (500) |

1 - 3 |

Appropriate standard for optical microscopes to 1000X, inspection and lithography inspection equipment (including moderately sensitive electron microscopes) to 1 μm detail size, TFT-LCD stepper/scanner processes. |

| VC-D | 6.25 (250) |

0.1 - 0.3 |

Suitable in most instances for the most demanding equipment including electron microscopes (TEMs and SEMs) and E-Beam systems.. |

| VC-E | 3.12 (125) |

< 0.1 |

A challenging criterion to achieve. Assumed to be adequate for the most demanding of sensitive systems including long path, laser-based, small target systems, E-Beam lithography systems working at nanometer scales, and other systems requiring extraordinary dynamic stability. |

| VC-F | 1.56 (62.5) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| VC-G | .78 (31.3) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| NIST-A | NIST-A criterion is identical to the VC-E curve at frequencies above 20 Hz, but maintains constant displacement at frequencies below this. 0.025 μm or 25 nm between 1 and 20 Hz; 3.1 μm /s (125 μ in /s) between 20 and 100 Hz | ||

| NIST-A1 | NIST-A1 criterion requires an RMS velocity of 3 μm/sec (118 μin./sec) for frequencies less than 4 Hz, and 0.75 μm/sec (29.5 μin./sec) velocity for frequencies 4 Hz < f < 100 Hz | ||

| VC-H | .39 (15.63) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| VC-I | .195 (7.81) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| VC-J | .097 (3.9) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| VC-K | .048 (1.95) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| VC-L | .024 (0.98) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| VC-M | .012 (0.49) |

N/A |

Appropriate for extremely quiet research spaces; generally difficult to achieve in most instances, especially cleanrooms. Not recommended for use as a design criterion, only for evaluation. |

| 1As measured in one-third octave bands of frequency over the frequency range 8 to 80 Hz (VC-A and VC-B) or 1 to 80 Hz (VC-C through VC-G) |

| 2The detail size refers to line width in the case of microelectronics fabrication, the particle (cell) size in the case of medical and pharmaceutical research, etc. It is not relevant to imaging associated with probe technologies, AFMs, and nanotechnology. |

| The information given in this table is for guidance only. In most instances, it is recommended that the advice of someone knowledgeable about applications and vibration requirements of the equipment and processes be sought. |

| This table is a reference of Colin Gordon Associates ,except (3&4).3Vibro-Acoustic Consultants,4Purdue University Libraries. |

| 5 NIST-A1 criterion was for the NIST AML (0.75 mm/s at frequencies between 4 and 100 Hz). NIST AML has a quantity of vibration-isolated spaces, created by placing large concrete blocks on air springs. If these had been used in a space just meeting NIST-A, then the performance would be on the order of NIST-A1, accounting for degradation at internal resonances. This was more of a philosophy than a set criterion amplitude. |

Transmissibility charts-graphs-curves by isolator...