Passive Vibration Isolation

As it relates to vibration isolation table, platform and

bench top systems developed by Minus K Technology

Vibrations can be isolated from equipment using active or

passive technology. With active methods, equal but opposite

forces are created electronically using sensors and actuators

to cancel out the unwanted vibrations. With passive methods,

isolation is achieved by limiting the ability of vibrations

to be coupled to the item to be isolated. This is done using

a mechanical connection which dissipates or redirects the

energy of vibration before it gets to the item to be isolated.

Passive methods sometimes involve electromechanical controls

for adjusting the system, but the isolation mechanism itself

is passive. Passive systems may use elastomers, springs, fluids,

or negative-stiffness components. Passive systems generally

cost less than active systems and their relative simplicity

makes them more reliable and safe.

One of the most basic passive isolators is a spring

placed between the surface transmitting shock or vibration

and the item to be isolated. The spring opposes the impulse

on it and absorbs some energy as it deforms. A fluid or

elastomeric element is added to the spring element for

damping. A simple example is the shock absorber in a car.

In this case, mechanical energy from the shock or vibration

does work on the fluid and is converted to thermal energy

in the fluid, reducing the amount of energy transmitted

to the body of the car.

One of the most basic passive isolators is a spring

placed between the surface transmitting shock or vibration

and the item to be isolated. The spring opposes the impulse

on it and absorbs some energy as it deforms. A fluid or

elastomeric element is added to the spring element for

damping. A simple example is the shock absorber in a car.

In this case, mechanical energy from the shock or vibration

does work on the fluid and is converted to thermal energy

in the fluid, reducing the amount of energy transmitted

to the body of the car.

Elastomers are rubber-like materials which

absorb mechanical energy by deforming. Examples of elastomeric

isolators are shock and vibration mounts for automobile

engines, aircraft components, industrial machinery, and

building foundations. Because rubber does not have the

same characteristics in all directions, isolation may

be much better in one axis than the others.

Elastomers are rubber-like materials which

absorb mechanical energy by deforming. Examples of elastomeric

isolators are shock and vibration mounts for automobile

engines, aircraft components, industrial machinery, and

building foundations. Because rubber does not have the

same characteristics in all directions, isolation may

be much better in one axis than the others.

The most sophisticated passive isolators use air or negative-stiffness

technology. In advanced technology applications, such as interferometry,

microscopy (including SPM, SEM, etc.), nano-fabrication and

micro-hardness testing, the best passive vibration isolation

devices allow the instruments to perform at their highest possible

level.

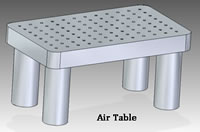

Pneumatic systems support a heavy table

or platform on compressed air pistons, which provide the

decoupling link between the ground and the table, i.e.

the table floats on the air. The most sophisticated air

tables do a good job of isolating floor vibrations at

small amplitudes, but can be quite expensive. While they

isolate in a passive manner, they require an air supply,

a leveling system, and associated maintenance and controls.

The less sophisticated air systems do not isolate well

in all directions or at the low frequencies which are

handled so well by negative-stiffness systems. The air

supply system for pneumatic isolators can create problematic

ambient vibration. The use of electrical methods of leveling

the table and controlling air cylinder pressure adds complexity

and the potential for failure.

Pneumatic systems support a heavy table

or platform on compressed air pistons, which provide the

decoupling link between the ground and the table, i.e.

the table floats on the air. The most sophisticated air

tables do a good job of isolating floor vibrations at

small amplitudes, but can be quite expensive. While they

isolate in a passive manner, they require an air supply,

a leveling system, and associated maintenance and controls.

The less sophisticated air systems do not isolate well

in all directions or at the low frequencies which are

handled so well by negative-stiffness systems. The air

supply system for pneumatic isolators can create problematic

ambient vibration. The use of electrical methods of leveling

the table and controlling air cylinder pressure adds complexity

and the potential for failure.

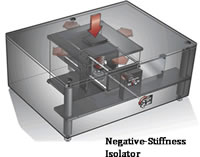

Negative-stiffness isolators provide a simple, reliable,

and highly effective isolation solution for sensitive

instrumentation at the low frequencies and amplitudes

of floor and building vibrations. They are relatively

small, light weight, stable, and cost-effective. Minus

K negative-stiffness isolators are completely mechanical;

for special applications, an optional electronic auto-adjust

system is available. Isolation is achieved using an arrangement

of springs and negative-stiffness mechanisms. These systems

provide isolation in 6 degrees of freedom with resonant

frequencies as low as 0.5 Hz or lower. For a 0.5-Hz system,

isolation begins around 1 Hz and is 50-100 times better

than most high-performance air tables in the 5-10 Hz range

which is so important in buildings. Multiple isolators

can be used together while still acting as one with respect

to vibration, which allows great versatility in designing

for a range of applications. Minus K's negative-stiffness

technology has been successfully implemented for sensitive

instrumentation loads from a few pounds to many tons.

The isolators are easy to use and adjust. They can be

more economical than air systems, take up less space,

provide better isolation at very low vibration amplitudes,

and require no maintenance.

Negative-stiffness isolators provide a simple, reliable,

and highly effective isolation solution for sensitive

instrumentation at the low frequencies and amplitudes

of floor and building vibrations. They are relatively

small, light weight, stable, and cost-effective. Minus

K negative-stiffness isolators are completely mechanical;

for special applications, an optional electronic auto-adjust

system is available. Isolation is achieved using an arrangement

of springs and negative-stiffness mechanisms. These systems

provide isolation in 6 degrees of freedom with resonant

frequencies as low as 0.5 Hz or lower. For a 0.5-Hz system,

isolation begins around 1 Hz and is 50-100 times better

than most high-performance air tables in the 5-10 Hz range

which is so important in buildings. Multiple isolators

can be used together while still acting as one with respect

to vibration, which allows great versatility in designing

for a range of applications. Minus K's negative-stiffness

technology has been successfully implemented for sensitive

instrumentation loads from a few pounds to many tons.

The isolators are easy to use and adjust. They can be

more economical than air systems, take up less space,

provide better isolation at very low vibration amplitudes,

and require no maintenance.

Negative-stiffness systems are typically not designed to handle large angular changes and shock loads such as occur in vehicle or aircraft applications. However, the Minus K devices can be used selectively to greatly enhance the performance of sensitive instruments during operations in vehicles or aircraft. Both pneumatic and negative-stiffness systems can be sensitive to temperature change but can be adjusted to compensate. Negative-stiffness systems can easily be used in a vacuum chamber or clean room, while air systems are prone to difficulties in this environment.

In addition to the standard products, Minus K designs custom

systems for special applications.