|

|

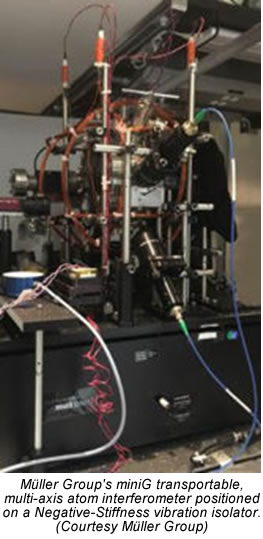

Professor Holger Müller's Group at UC

Berkeley is focused on advancing experimental quantum technology to push the

sensitivity of experiments to new levels, and to perform precision measurements

of fundamental constants. The groups work uses methods from atomic, molecular

and optical physics. One project is the development of a transportable,

multi-axis atom interferometer, named miniG.

MiniG was designed to

research how quantum interference can be used to measure gravity outside of the

laboratory. When cooled to just above absolute zero, the atoms form the focus

of a portable quantum gravimeter.

Gravimeters, used to measure

gravitational acceleration, have been successfully applied for metrology,

geology and geophysics. MiniG uses an atom interferometer to measure the effect

of gravity on clouds of atoms that are first trapped and cooled. Interferometry

inherently depends on the wave nature of the object. Particles, including

atoms, can behave like waves. Atom interferometers measure the difference in

phase between atomic matter waves along different paths.

We use atoms

that are laser-cooled to millionths of a degree above absolute zero, said

Xuejian Wu, a post-doctoral scholar, involved in the development of miniG at

the Müller Group. With pulses of light, we drive each atom into a quantum

superposition of having been kicked with the momentum of photons, or not

kicked. The atoms, in two places at one time, are in a superposition of

recoiling backwards or staying still. By manipulating the state of the atoms

using one of two types of such light pulses, we steer the matter waves' paths

and recombine the matter waves at the end of the experiment.

Atom

interferometry has become one of the most powerful technologies for precision

measurements, and atomic gravimeters, based on atom interferometry, are

extremely accurate and have long-term stability.

Current atom

interferometers, however, are too complicated to operate in a miniature package

or under field conditions. Berkeleys mini-G was engineered to resolve this

issue.

In this project, we are developing a mobile atom interferometer

using a single-diode laser system and a pyramidal magneto-optical trap,

continued Wu. This allows the device to be smaller, simpler and more robust

than conventional atom interferometers.

Vibration

Isolation

Measurements of atomic precision require

isolation from ambient vibrations coming from internal and external sources. As

measurements are being done at a smaller and smaller level, those vibrations

that are present will start to dominate, and the need for more effective

isolation increases.

Although the Müller Groups research

laboratory is situated in the basement of a building on the Berkeley campus, it

is still influenced by vibrations from the buildings HVAC system.

For

several years now we have been using

Negative-Stiffness vibration isolation for our

research projects, continued Wu.

Full article...

|

|

|

The United States Bowling Congress

(USBC) is the national governing body of bowling, as recognized by the United

States Olympic Committee. It is a membership organization that provides

standardized rules, regulations and benefits for certified bowling leagues and

tournaments. The USBC is one of the worlds largest sports and recreation

membership organizations, in the United States serving approximately 1.4

million bowlers that participate in USBC-certified leagues and tournaments on

both the national and local levels.

Critical to the initiatives of the

USBC is its Department of Equipment Specifications and Certification, which

encompasses testing and research of bowling equipment to set standards and

enhance the sports credibility.

“There are two sides to bowling

– the recreational, and the more competitive,” said Tom Frenzel,

Research Engineer with the USBC. “Our focus is on research, testing,

standardization and certification of bowling equipment used for leagues and

tournaments.”

“Basically, any piece of equipment that

touches the bowling lane comes though this department to be evaluated, and

determined whether or not it should be allowed to be used,” added Frenzel.

“This includes bowling pins, bowling balls, lane panels, lane

conditioners, gutters, and kick-back walls in the pin deck.”

To this end, the department uses a number of research and testing

methodologies to ensure that not only do these products meet established

specifications, but that they are manufactured to within a 4 Sigma quality

manufacturing limit, which means within a 0.6 percent defect rate. Essentially,

ensuring that 99.4 percent of all bowling products used for certified leagues

and tournaments are within designated specifications.

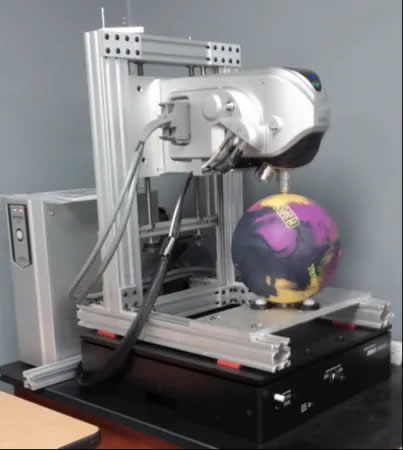

Minus K

Negative-Stiffness vibration isolator,

under a 3D laser-scanning, digital

confocal microscope.

Surface Roughness of Bowling

Balls

One area of ongoing research and testing at USBC concerns surface

roughness of bowling balls.

Since the early 1990s, better bowling ball

coverstocks have been developed. These coverstocks find more friction on the

lane, and inevitably hook more. They also disrupt the oil pattern on the lane

more, which tends to reduce friction. So the USBC engineering team is trying to

better understand the implications of these factors, and better control their

outcomes.

It has become popular to sand bowling balls with different

grits of sand paper, explained Frenzel. This practice has helped us see how the

sanding level on a ball affects its surface layer, then we compare this back to

how it performs on the lane.

The rougher you get the ball, the more the

ball will hook, and the more friction it will find, continued Frenzel. The

friction will define how the ball accelerates. So more friction means more

acceleration, which just means it is changing its speed quicker, or in less

time. It is really hooking sooner versus later, or taking less time to

hook.

Full article...

|

|

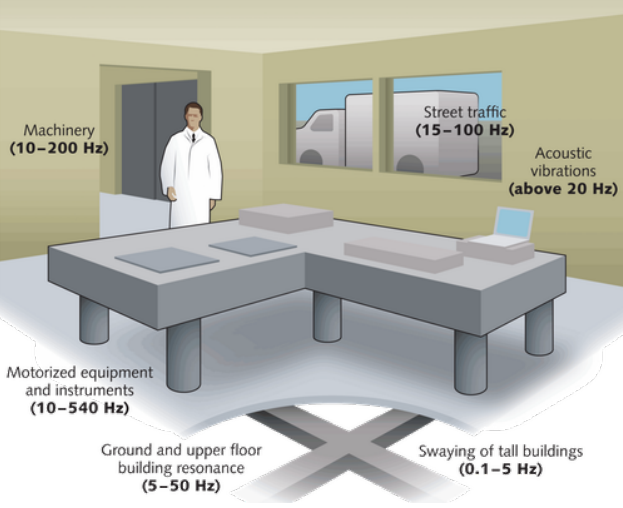

(2007 legacy article) - Whether it's an NMR

or a two-photon microscope, scientists love toys - at least when they work.

Sometimes the most mundane things bungle technology: environmental

vibrations from cars driving by, central air conditioning, the voices of the

operators, and even the ocean. As instruments become more sensitive,

subsonic rumblings become more insidious, particularly for nano-technology

applications. With many instruments, such as atomic-force and electron

microscopes, cutting down on vibration is essential to collecting good data.

"You could spend a million or two million on a microscope and have it rendered

useless because of vibration," says Kurt Alberline, an anatomist at the

University of Utah School of Medicine, who runs an electron microscopy

lab.

When researchers suspect vibration is wreaking havoc on their data,

they should identify the origin of the noise or get an environmental engineer

to find it, say scientists who regularly deal with vibration. For example,

Vicki Colvin, a chemist at Rice University in Houston, noticed images moving

around in a circle on her transitional electron microscope. "It was like a

ghost," she says. Colvin discovered that an air duct was causing the problem

and spent $1.20 on a shield to divert air away from the scope. "The easiest way

to get rid of vibrational noise is to stop it at its source." says Larry Cohen,

a neuroscientist at Yale University.

The design of a building is

critical to the vibration that reaches an instrument, says Ahmad Soueid, senior

vice president at HDR Architecture in Omaha, Neb., which has designed more than

a dozen nanotech laboratories. Isolating air-handling equipment from

laboratories and using special joints that redirect vibration to the ground are

some of the fixes his firm uses. Recently, concerns over vibration plagued a

$250 million NIH facility under construction in Baltimore. Initial reports

indicated the building's quivers could render confocal microscopes useless,

although later measurements suggested most instruments will work with proper

dampening

There's no universal fix, says David Platus, president of

Minus K, a company that makes high-end vibration-isolation tables. Solutions

vary, from cheap rubber pads that rest under instruments, to the air-cushioned

tables that have been around for 50 years, to tables that sense vibration and

cancel it out. "The more sensitive the instrument, the better isolation you

need." he says.

Full article...

Example Causes of Bad

Vibrations:

Automotive

Buildings

Columns

Computers

Elevators

Engines/Motors

Floors

Freeway & Road Traffic

Generators

HVAC (Heating & Air Conditioning Issues)

Machinery

Mechanical Entities

Plumbing, Piping

Pneumatic factors

Seismic Waves

(including from ocean waves)

Trains & Subways

Transformers

Winds

Against Buildings

(Examples with

Hz...)

|

|

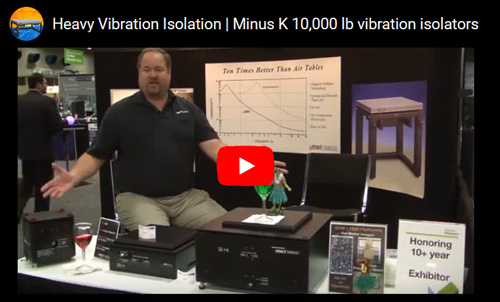

Vibration Isolation for Heavy

Payload Systems

Minus K vibration isolation systems can be

designed for very heavy payloads. The following are some typical isolator

dimensions. The 10,000 lb and 25,000 lb isolator dimensions are approximate and

are based on preliminary designs.

XM-1:

10,000 lb capacity: 20"W x 20"D x 22"H

The James Webb

Space Telescope is the largest cryogenic instrument telescope to be developed

for space flight. It is a large-aperture infrared space telescope and the

scientific successor to NASA's Hubble Space Telescope and used a set of six

custom heavy capacity Minus K vibration isolators for ground testing.

The ground testing confirmed the telescope and science instrument

systems will perform properly together in the cold temperatures of space.

Additional test support equipment including mass spectrometers, infrared

cameras and television cameras were also supported by Minus Ks heavy capacity

vibration isolators which allowed engineers to observe the testing.

Each of the isolators was designed for 10,000 lbs. and the total

payload supported from the top of the Johnson Space Center vacuum Chamber A was

60,000 lbs.

The isolators allowed NASA to simulate the telescopes

performance in space while preventing all the ground-based disturbances, such

as the pumps and motors, and even traffic driving by from interfering with the

ground testing. Case

study:

NASA James Webb Space Telescope

(JWST).

|

Press

Release: Minus K Receives Laser

Focus World Innovator Award for

Ultra-Thin, Low-Height

CT-1

Vibration Isolation Platform

The awards

were given to companies or organizations that demonstrated

excellence in a

product or technology,

an application, or in research and development.

(November 25, 2019,

Inglewood, California) - For the second year, Laser Focus World held its

Innovators Awards program, which celebrates the disparate and innovative

technologies, products, and systems found in the photonics market. The awards

were given to companies or organizations that demonstrated excellence in a

product or technology, an application, or in research and development.

Full

release...

|

|

|

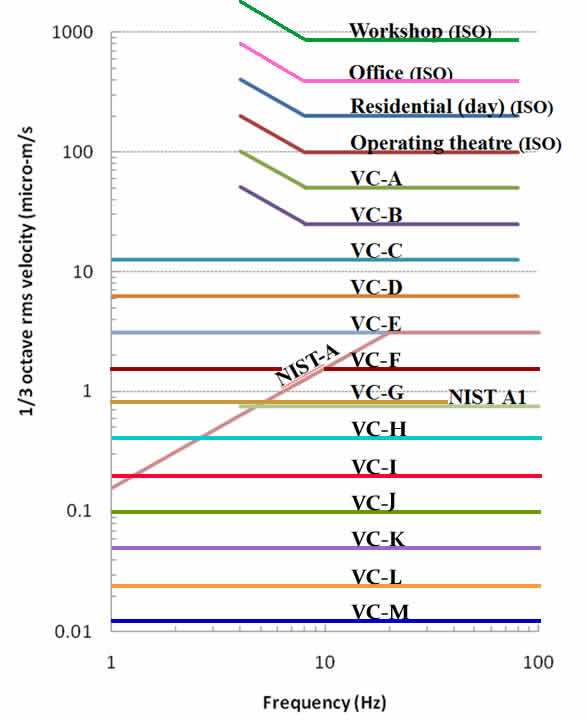

Vibration Criterion (VC)

Curves-Lab Analysis

Codes and curve descriptions for different

vibration environments and solutions.

The VC

(Vibration Criteria) curves were developed in the early 1980s by Eric Ungar and

Colin Gordon. They were originally developed as a generic vibration criteria

for vibration-sensitive equipment for use in the semiconductor, medical and

biopharmaceutical industries, but have found application in a wide variety of

technological applications.

The criteria takes the form of a set of

one-third octave band velocity spectra, together with the International

Standards Organization (ISO) guidelines for the effects of vibration on people

in buildings. The criteria apply to vibration as measured in the vertical and

two horizontal directions.

The

NIST-A criterion was developed for metrology, but has gained popularity within

the nanotechnology community. The NIST-A criterion is a very difficult

criterion to meet at some sites with significant low-frequency

vibrations.

The VC curves are now widely accepted throughout the world

as a basis for designing a facility to meet the requirements of a group of

highly vibration sensitive equipment used close together.

University of

Michigans Ultra-Low Vibration Lab (ULVL) was completed in 2014. After the

construction, a vibration survey was done on the Ultra-Low Vibration Lab

chambers. The measurements demonstrated that even when a single vehicle was

driving on a nearby street, the vibrations exceeded the NIST-A specifications

necessary for the ULVL.

The University of Michigan ordered seven

customized tabletops and 31 custom Minus K Negative-Stiffness vibration

isolators with pedestals provided for the eight Ultra-Low Vibration Lab

chambers.

Customized Minus K

Technology Negative-Stiffness vibration isolation table installed in one of the

Ultra-Low Vibration Lab chambers

The

final vibration survey by Colin Gordon Associates (CGA), after installation of

the customized Minus K Negative-Stiffness isolators and tables, showed the

measured vibration levels in all ULVL chambers from VC-K to VC-M at frequencies

above 2.5 Hz, well below the NIST-A Vibration Criterion required.

"VC-M

is the lowest we have ever measured, though we werent able to measure below 2.5

Hz because our most sensitive sensor wont go lower, due to sensor noise floor,"

said Hal Amick, Vice President of Colin Gordon Associates.

The updated

VC Curve on Minus K's

website shows these lower curve levels that were measured by CGA

and have already assisted University of Michigans ULVL with two major

scientific milestones.

Vibration site surveys can tell you a

lot about how to

specify equipment for vibration isolation in your

laboratory.

Updated

VC Curve on Minus K's website... |

Previous

Features:

How They

Work>>Negative-Stiffness Vibration Isolators

Microscopy Vibration

Isolation

FAQs>>Frequently Asked

Questions About Vibration Isolation

Custom Vibration Isolation

Systems

Audio Reproduction & Turntable

Vibration Isolation

Vibration Isolator Steadies Optics

for NASA Telescopes + Vacuum Isolation

Optical-Laser Vibration Isolation +

video

Optical-Laser Vibration Isolation +

video

Cryostat Vibration

Isolation

Nanoindentation & Micro Hardness

Testing

Vibration Isolation

Ultra-Low Frequency Vibration

Isolation Stabilizes Scanning Tunneling Microscopy

Neuronal Research into Animal

Learning, Memory Neuronal Research,

Vibration Isolation Problem &

Solution

Sunken Treasure Surrounding The

Coldest Cubic Meter In The Universe

Supported by Minus K Vibration

Isolators

Lithium Batteries: Superionic Solid

Electrolytes for Next-Generation

Spacecraft Vibration Isolation On the

Ground

Behavior of a Single Molecule-UCLA's

California NanoSystems Institute

Cleanroom Precision Vibration

Isolation

Negative-stiffness vibration

isolation is utilized to provide ultra-stability for multi-disciplined,

nano-level research at UCLA's California NanoSystems

Institute.

NASA/JWST Update: Custom James Webb

Space Telescope Vibration Isolators Working Well

Audiophile Interests: The Doehmann

Helix 1 Turntable

Minus K Technology Educational

Giveaway to U.S. Colleges and Universities

Articles In The

News

|