|

|

Newsletter November 2019

|

|

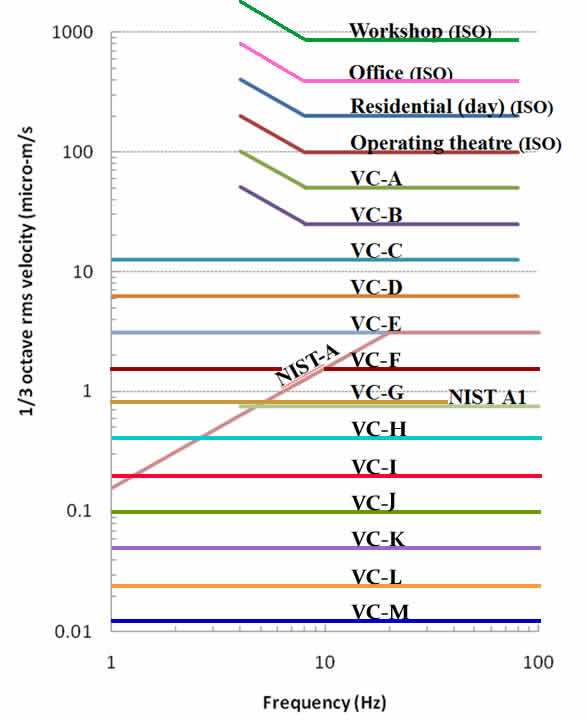

Vibration Criterion (VC)

Curves-Lab Analysis

Codes and curve descriptions for different

vibration environments

and enviromental solutions.

The VC

(Vibration Criteria) curves were developed in the early 1980s by Eric Ungar and

Colin Gordon. They were originally developed as a generic vibration criteria

for vibration-sensitive equipment for use in the semiconductor, medical and

biopharmaceutical industries, but have found application in a wide variety of

technological applications.

The criteria takes the form of a set of

one-third octave band velocity spectra, together with the International

Standards Organization (ISO) guidelines for the effects of vibration on people

in buildings. The criteria apply to vibration as measured in the vertical and

two horizontal directions.

The

NIST-A criterion was developed for metrology, but has gained popularity within

the nanotechnology community. The NIST-A criterion is a very difficult

criterion to meet at some sites with significant low-frequency

vibrations.

The VC curves are now widely accepted throughout the world

as a basis for designing a facility to meet the requirements of a group of

highly vibration sensitive equipment used close together.

University of

Michigans Ultra-Low Vibration Lab (ULVL) was completed in 2014. After the

construction, a vibration survey was done on the Ultra-Low Vibration Lab

chambers. The measurements demonstrated that even when a single vehicle was

driving on a nearby street, the vibrations exceeded the NIST-A specifications

necessary for the ULVL.

The University of Michigan ordered seven

customized tabletops and 31 custom Minus K Negative-Stiffness vibration

isolators with pedestals provided for the eight Ultra-Low Vibration Lab

chambers.

Customized Minus K

Technology Negative-Stiffness vibration isolation table installed in one of the

Ultra-Low Vibration Lab chambers

The

final vibration survey by Colin Gordon Associates (CGA), after installation of

the customized Minus K Negative-Stiffness isolators and tables, showed the

measured vibration levels in all ULVL chambers from VC-K to VC-M at frequencies

above 2.5 Hz, well below the NIST-A Vibration Criterion required.

"VC-M

is the lowest we have ever measured, though we werent able to measure below 2.5

Hz because our most sensitive sensor wont go lower, due to sensor noise floor,"

said Hal Amick, Vice President of Colin Gordon Associates.

The updated

VC Curve on Minus K's

website shows these lower curve levels that were measured by CGA

and have already assisted University of Michigans ULVL with two major

scientific milestones.

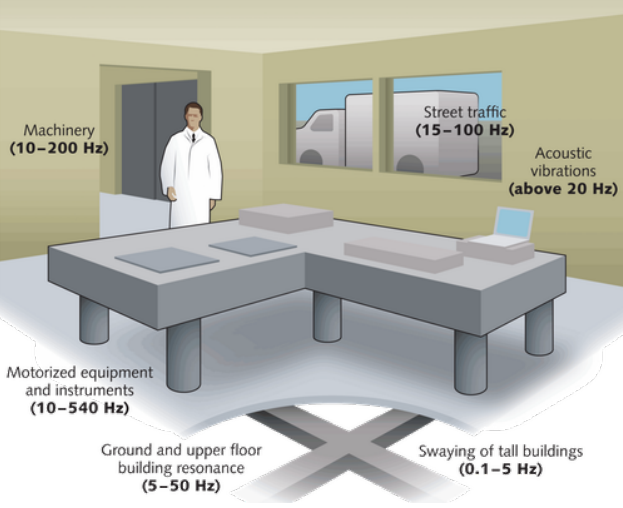

Vibration site surveys can tell you a

lot about how to

specify equipment for vibration isolation in your

laboratory.

| Curve

Criterion |

Amplitude1

µm/s

(µin/s) |

Detail Size2

µm

|

Description of

Use |

| Workshop (ISO) |

800( 32,000) |

N/A |

Distinctly perceptible vibration.

Appropriate to workshops and non-sensitive areas. |

| Office (ISO) |

400 (16,000) |

N/A |

Perceptible vibration. Appropriate to

offices and non-sensitive areas |

| Residential Day (ISO) |

200 (8000) |

75 |

Barely perceptible vibration. Appropriate

to sleep areas in most instances. Usually adequate for computer equipment,

hospital recovery rooms, semiconductor probe test equipment and microscopes

less than 40x. |

| Op. Theatre (ISO) |

100 (4000) |

25 |

Vibration not perceptible. Suitable in

most instances for surgical suites, microscopes to 100X and for other equipment

of low sensitivity. |

| VC-A |

50 (2000) |

8 |

Adequate in most instances for optical

microscopes to 400X, microbalances, optical balances, proximity and projection

aligners, etc. |

| VC-B |

25 (1000) |

3 |

Appropriate for inspection and lithography

(including steppers) to 3 µm line widths.. |

| VC-C |

12.5 (500) |

1 - 3 |

Appropriate standard for optical

microscopes to 1000X, inspection and lithography inspection equipment

(including moderately sensitive electron microscopes) to 1 µm detail

size, TFT-LCD stepper/scanner processes. |

| VC-D |

6.25 (250) |

0.1 - 0.3 |

Suitable in most instances for the most

demanding equipment including electron microscopes (TEMs and SEMs) and E-Beam

systems.. |

| VC-E |

3.12 (125) |

< 0.1 |

A challenging criterion to achieve.

Assumed to be adequate for the most demanding of sensitive systems including

long path, laser-based, small target systems, E-Beam lithography systems

working at nanometer scales, and other systems requiring extraordinary dynamic

stability. |

| VC-F |

1.56 (62.5) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| VC-G |

.78 (31.3) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| NIST-A |

|

|

NIST-A criterion is identical to the VC-E

curve at frequencies above 20 Hz, but maintains constant displacement at

frequencies below this. 0.025 µm or 25 nm between 1 and 20 Hz; 3.1

µm /s (125 µ in /s) between 20 and 100 Hz |

| NIST-A1 |

|

|

NIST-A1 criterion requires an RMS velocity

of 3 µm/sec (118 µin./sec) for frequencies less than 4 Hz, and 0.75

µm/sec (29.5 µin./sec) velocity for frequencies 4 Hz < f <

100 Hz |

| VC-H |

.39 (15.63) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| VC-I |

.195 (7.81) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| VC-J |

.097 (3.9) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| VC-K |

.048 (1.95) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| VC-L |

.024 (0.98) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| VC-M |

.012 (0.49) |

N/A |

Appropriate for extremely quiet research

spaces; generally difficult to achieve in most instances, especially

cleanrooms. Not recommended for use as a design criterion, only for

evaluation. |

| 1 As

measured in one-third octave bands of frequency over the frequency range 8 to

80 Hz (VC-A and VC-B) or 1 to 80 Hz (VC-C through VC-G) |

| 2

The detail size refers to line width in the case of microelectronics

fabrication, the particle (cell) size in the case of medical and pharmaceutical

research, etc. It is not relevant to imaging associated with probe

technologies, AFMs, and nanotechnology. |

|

The information given in

this table is for guidance only. In most instances, it is recommended that the

advice of someone knowledgeable about applications and vibration requirements

of the equipment and processes be sought. |

This table is a reference of Colin

Gordon Associates ,except (3&4).

3 Vibro-Acoustic Consultants,

4 Purdue

University Libraries.. |

| 5

NIST-A1 criterion was for the NIST AML (0.75 mm/s at frequencies between 4 and

100 Hz). NIST AML has a quantity of vibration-isolated spaces, created by

placing large concrete blocks on air springs. If these had been used in a space

just meeting NIST-A, then the performance would be on the order of NIST-A1,

accounting for degradation at internal resonances. This was more of a

philosophy than a set criterion amplitude. |

Updated

VC Curve on Minus K's website... |

|

Featured Product: WS-4 Compact Vibration Isolation

Table

- Vertical natural frequency

of 1/2 Hz or less can be achieved over the entire load range.

- Horizontal natural

frequency is load dependent. 1/2 Hz or less can be achieved at or near the

nominal load.

- Horizontal natural

frequency is load dependent. 1/2 Hz or less can be achieved at or near the

nominal load.

- Dimensions: 24" W x 24" D

x 23" H

(610mm W x 610mm D x 533mm H)

A cost

effective vibration isolation table for weight loads up to 1000 lb. and 1/2 Hz

performance vertical and horizontal. A cost

effective vibration isolation table for weight loads up to 1000 lb. and 1/2 Hz

performance vertical and horizontal.

The stand has been designed with a

damped Phenolic top which includes locating holes for the leveling feet of the

BM-1 and

BM-4.

Pricing & Specifications

|

|

How They

Work>>Negative-Stiffness Vibration Isolators

Minus K®

vibration isolators employ a revolutionary concept in

low-frequency vibration isolation. Vertical-motion isolation is provided by a

stiff spring that supports a weight load, combined with a negative-stiffness

mechanism (NSM). The net vertical stiffness is made very low without affecting

the static load-supporting capability of the spring. Beam-columns connected in

series with the vertical-motion isolator provide horizontal-motion isolation.

The horizontal stiffness of the beam-columns is reduced by the "beam-column"

effect. (A beam-column behaves as a spring combined with an NSM.) The result is

a compact

passive isolator capable of very low vertical and

horizontal natural frequencies and very high internal structural

frequencies.

Figure 1 |

|

Minus K®

isolators typically use three isolators stacked in series:

A

tilt-motion isolator on top of a horizontal-motion isolator on top of a

vertical-motion isolator. A vertical-motion isolator is shown in

Figure

1. It uses a conventional spring connected to an NSM consisting of two

flexures connected at their inner ends to the spring and supported at their

outer ends, and loaded in compression by forces P. The spring is compressed by

weight W to the operating position of the isolator, as shown in Figure 1. The

stiffness of the isolator is K=KS-KN where KS is the spring stiffness and KN is

the magnitude of a negative stiffness which is a function of the design of the

flexures and the load P. The isolator stiffness can be made to approach zero

while the spring supports the weight W. |

A

horizontal-motion isolation system consisting of two beam-column isolators is

shown in Figure 2. Each isolator behaves like two fixed-free beam

columns loaded axially by a weight load W. Without the weight load the

beam-columns have horizontal stiffness KS. With the weight load the lateral

bending stiffness is reduced by the "beam-column" effect. This behavior is

equivalent to a horizontal spring combined with an NSM so that the horizontal

stiffness is K=KS-KN, and KN is the magnitude of the beam-column effect.

Horizontal stiffness can be made to approach zero by loading the beam-columns

to approach their critical buckling load.

Full article +

more images...

Performance... |

|

Custom Vibration Isolation

Systems

Minus K engineers can design a variety of custom vibration

isolation systems. Frequently these are modifications of other designs such as

changing the load capacity of an

SM-1 isolator, or the capacity, size and

isolator locations on a

FP-1.

Custom table top with four resessed Minus K

CM-1s and pedestals

|

Some other custom modifications and capabilities

include:

- Different

vertical, horizontal or tilt stiffness in an isolator

- Different

vertical, horizontal or tilt damping in an isolator

- Vacuum

compatibility

- Mildly

magnetic

- Heavy load

capacities

(Six 10,000 lb

isolators for NASA's James Webb

Space Telescope Ground

Testing).

- Large

displacements

- Large

temperature variations

- Compact systems

(e.g., a seven-inch cubic 1/2 Hz isolator for a 700 lb payload;

a six-inch

diameter by 4-inches tall 1/2 Hz vibration isolation platform for a 3 lb

payload.)

- Vertical

auto-adjust feature to automatically adjust for change in payload

weight.

- Lock-unlock

feature implemented manually with a switch or automatically

with signals,

from a stage motion control system, for example.

|

|

Audio Reproduction & Turntable

Vibration Isolation

Platforms, Tables, & Integrated

Systems

|

Since the early 2000s, Minus K Technology, the developer of

Negative-Stiffness vibration isolation, has released several vibration

isolation platforms for the high-end audio market. These products have been

accepted with high acclaim by audiophiles and audio system manufacturers

worldwide.

The industry's highest performing vibration isolation system

is available in a cost-effective, low-height platform. The

BM-8 Series vibration

isolation platform offers true ½-Hz isolation performance vertical and

1.5 Hz horizontal and is easy to use. No air or electric power is required,

there is no maintenance and nothing to wear out. It is 18Wx20Dx4.6H and is

available with nominal load capacities from 25 to 250 lbs. It is ideal for

turntables, CD transports and other audio components.

The Helix One®

and Helix Two® turntables from Dohmann Audio, for example, come fully

integrated with Negative-Stiffness vibration isolation.

Doehmann Helix 1 (BM-8 fully integrated)

Doehmann Helix 2 (BM-10 fully integrated)

“The ability

of Negative-Stiffness to deal with vibration and resonance is unsurpassed, and

allows the music to be enjoyed with an outstanding level of

realism.

Analog audiophile aficionados talk about blackberry notes,

where the base is too prominent and muddy, explained Dohmann. This is often

caused by a reinjection of vibration into the playback mechanism, adding to the

amplitude of the needle movement and creating more signal that what is

physically in the groove. But Negative-Stiffness vibration isolation cleans

this up, so that the base is more natural. The timbre of the instrument used to

produce the base, whether a string, piano or drum, sounds more like the real

thing. It enables a sense of peace and calm to the playback."

-

Mark Döhmann, Founder Döhmann Audio |

The latest generation of Negative-Stiffness vibration isolation

technology, embodied within the new ultra-thin, low-hieght Minus K

CT-1, truly represents

a significant advance in sound quality in a very compact package for high-end

audio perfectionists.

SAT (Swedish Analog Technologies) XD1 Record Player

System

with Minus K

CT-1 [integrated into the

platform]

|

“I have now tried the

CT-1 with the SAT top

platform the results are spectacular! I took a look at the mechanism inside of

the CT-1 and I have to say I am very impressed with the ingenious work you have

done. It provides most of its big brothers performance in an extremely compact

package that looks very slick. The arrangement and the finish of the mechanism

is an engineers dream and it should be proudly displayed. The equipment

supported by the CT-1 is well isolated from vibrations from 0.7 to 100 Hz, with

much deeper, clearer base and more information in the lower frequencies. The

CT-1 makes a huge difference in sound quality."

- Marc Gomez,

President / Swedish Analog Technologies SAT |

The

BM-1 Series platform

offers Minus K's signature 0.5 Hz performance, both vertical and horizontal,

and is available for larger and much heavier audio components.

The

BM-10 Series offers

smaller horzontal dementions at 12.2 W x 12.2 D x 4.6 H (310mm W x 310mm D x

117mm H).

More images, plus reviews and

testimonials...

|

|

Microscopy Vibration

Isolation

Tables, Platforms, Benchtops & Custom Systems for

SEM, AFM, TEM, SPM, STM, STEM, NSOM-SNOM

Zeiss Axio

Obersver Z1 AFM

on a Minus K

BM-8

|

Delong LVEM5

Desktop SEM

on a Minus K

BM-8

|

Nion STEM on a

four-isolator

Minus K

FP-1

|

NanoMagnetics

ezAFM

on a Minus K

50BM-4

|

|

Many

of our clients' microscopes have nano and micro vibration isolation

requirements that are unparalleled in the metrology world (for

brain

research and at

NASA as examples). Minus K's negative

stiffness and "passive" verses "active" technology, enables microscopes to

achieve their highest level of performance. Our

isolators and

custom systems provide the performance of an

ideal bungee system and the convenience of a bench top system without any of

the problems associated with many of them, including air tables.

From

the ubiquitous bungee suspension systems, to large beds of sand on inner tubes,

there have been many attempts at achieving the ultimate isolation. Air tables

have been used with some success. However, our negative-stiffness isolators

provide superior isolation control and performance while offering better ease

of use and no facility requirements. We even have the flexibility of custom

tailoring resonant frequencies vertically, horizontally and in tilt to your

liking.

Small "active" systems (as opposed to our "passive" systems) are

sometimes used. However, those have several drawbacks:

- They are

expensive and fragile.

- They are

subject to the noise floor of every component in the entire feedback loop plus

AC line noise.

- They

have a limited dynamic range, typically only a few thousandths of an inch. If

this is exceeded (very easy to do) the isolator goes into positive feedback and

you have a very expensive noise generator underneath your SPM.

- They

have to be sitting on an infinitely rigid structure to work at their

theoretical best. Obviously, infinitely rigid structures are not easy to find

in most labs. The result is that the isolator is not always doing what you

think it's doing.

|

Our

isolators give you the best possible

performance in all axes, from high to low frequency isolation. They provide the

performance of an ideal bungee system and the convenience of a bench top system

without any of the problems associated with any of them, including air tables.

We enable our users to achieve the highest level of noise performance possible.

|

|

|

|

|

|

|