|

|

Newsletter June 2019

|

Microscopy Vibration

Isolation

Tables, Platforms, Benchtops & Custom Systems for

SEM, AFM, TEM, SPM, STM, STEM, NSOM-SNOM

Zeiss Axio

Obersver Z1 AFM

on a Minus K

BM-8

|

Delong LVEM5

Desktop SEM

on a Minus K

BM-8

|

Nion STEM on a

four-isolator

Minus K

FP-1

|

NanoMagnetics

ezAFM

on a Minus K

50BM-4

|

|

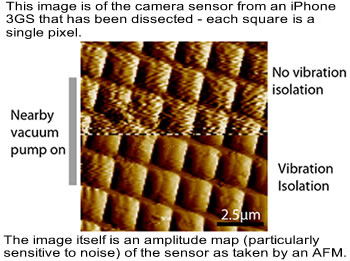

Many of

our clients' microscopes have nano and micro vibration isolation requirements

that are unparalleled in the metrology world (for

brain

research and at

NASA as examples). Minus K's negative

stiffness and "passive" verses "active" technology, enables microscopes to

achieve their highest level of performance. Our

isolators and

custom systems provide the performance of an

ideal bungee system and the convenience of a bench top system without any of

the problems associated with many of them, including air tables.

From

the ubiquitous bungee suspension systems, to large beds of sand on inner tubes,

there have been many attempts at achieving the ultimate isolation. Air tables

have been used with some success. However, our negative-stiffness isolators

provide superior isolation control and performance while offering better ease

of use and no facility requirements. We even have the flexibility of custom

tailoring resonant frequencies vertically, horizontally and in tilt to your

liking.

Small "active" systems (as opposed to our "passive" systems) are

sometimes used. However, those have several drawbacks:

- They are

expensive and fragile.

- They are

subject to the noise floor of every component in the entire feedback loop plus

AC line noise.

- They have a

limited dynamic range, typically only a few thousandths of an inch. If this is

exceeded (very easy to do) the isolator goes into positive feedback and you

have a very expensive noise generator underneath your SPM.

- They have to

be sitting on an infinitely rigid structure to work at their theoretical best.

Obviously, infinitely rigid structures are not easy to find in most labs. The

result is that the isolator is not always doing what you think it's doing.

|

Our

isolators give you the best possible

performance in all axes, from high to low frequency isolation. They provide the

performance of an ideal bungee system and the convenience of a bench top system

without any of the problems associated with any of them, including air tables.

We enable our users to achieve the highest level of noise performance possible.

|

|

|

Anybody who has ever

tried to hold a camera steady for a long exposure in low light knows exactly

what inevitably happens: the camera shakes, and the image blurs. The same can

happen with images from telescopes or any other long-range image. In fact, for

some very sensitive optics, even ordinary ground vibrations can be enough to

throw off the results.

Thats why, explains Serge Dubovitsky, instrument

system engineer at the Jet Propulsion Laboratory (JPL), NASA often needs a tool

called a vibration isolator. These work in a few different ways but essentially

create a more stable platform where external vibrations wont interfere with

sensitive measurements..

Dubovitsky often works on optics, including

systems of mirrors for observational missions like telescopes. The mirrors

reflect light in different wavelengths, concentrating it into an image that can

be analyzed by other instruments. But before these optics are installed, they

have to be tested to ensure they perform as intended.

For optics that

operate in roughly visible wavelengths, says Dubovitsky, any motion on the

scale of one micron [that is, one-millionth of a meter], or in some cases even

much less than that, disturbs the image quality.

Optics testing is also often done in a vacuum, with

ramifications for vibration isolators. Vacuum is important in verifying optics,

because air interferes with light. If you are aiming at space applications, on

the ground you need vacuum, Dubovitsky explains. Even when working with optics

that will remain on the ground, a vacuum can be helpful for testing.

More...

Related: Spacecraft Vibration

Isolation On the Ground isolation...

Related: Vacuum Chamber Vibration

Isolation...

|

|

Minus K vibration

isolation systems offer significant advantages for patch clamping,

electrophysiology measurements, fluorescent dye imaging, genomic sequencing and

other applications in biology and neuroscience. They eliminate the nuisance of

air and outperform air tables by a factor of 10 to 100, depending on the

vibration frequency. The bench top platforms are compact, saving valuable lab

space, and are easy to move around.

Biology/Neuroscience

Testimonials

Vibration can be caused by a

multitude of factors that are internal and external to the building in which

the system resides, including vibrations from heating and ventilation system,

fans, pumps, and elevators as well as vibrations from adjacent road traffic,

nearby construction, loud noise from aircraft, and even wind and other weather

conditions that can cause movement of the structure. These internal and

external influences cause vibrations as low as 2 hertz (Hz) that can create

strong disturbances in sensitive equipment.

Pacific

Biosciences Automated Genomic Sequencer Sequel System with fully intergrated

customized Minus K

BM-6 |

|

Bruker Biospin

Ascend Aeon 950 NMR magnet with two fully intergrated customized Minus K

LC-4Us

|

Related article regarding Neurology

& Brain Imaging...

Related article regarding Neuronal

Research into Animal Learning and Memory... |

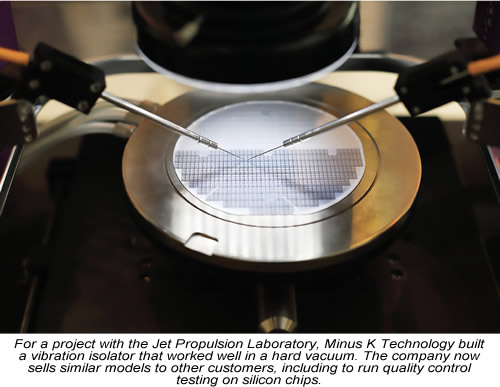

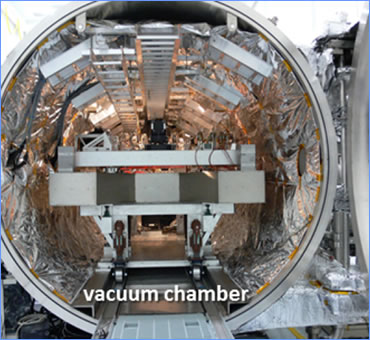

Vacuum Chamber Vibration

Isolation

Minus K

vibration isolation systems can be made vacuum compatible so they can be used

right inside vacuum chambers. In addition to their superior vibration

isolation performance, this offers other advantages of much lower payload

weights, more compact systems, and eliminates problems associated with vacuum

chamber feed-throughs. They require no electriciity or air, so they can operate

in isolation. See below example with NASA/JPL SIM Interferometer Testbed

Spectral Calibration Development Unit (SCDU).

Our vibration isolation

systems have also been used to support entire vacuum chambers. This

offers the advantages of more standard designs and lower costs in some cases.

|

Three 1350 lb capacity Vacuum Minus K

SM-1s for the

SCDU

in JPL's testbed configuration.

Minus K

BM-1 Vacuum

Isolation

Modifications for to the isolators based on your application

requirements could include:

• Use of Stainless Hardware

•

Removal of Paint and/or Powder Coating

• Removal of Anodizing

• Replacement of Nylon or Plastic Parts

• Electroless Nickel

on Steel Parts

• Venting Blind Holes

• Use of Vacuum Grease

for Low Outgassing

• Bare Aluminum

• We'll need to

provide custom

pricing for vacuum applications. The price is typically 3 times the standard

units for vacuum compatible (internal chamber) placement.

|

|

Vibration News &

Articles

Previous

Features:

Optical-Laser Vibration Isolation +

video

Cryostat Vibration

Isolation

Nanoindentation & Micro Hardness

Testing

Vibration Isolation

Ultra-Low Frequency Vibration

Isolation Stabilizes Scanning Tunneling Microscopy

Neuronal Research into Animal

Learning, Memory Neuronal Research,

Vibration Isolation Problem &

Solution

Sunken Treasure Surrounding The

Coldest Cubic Meter In The Universe

Supported by Minus K Vibration

Isolators

Lithium Batteries: Superionic Solid

Electrolytes for Next-Generation

Spacecraft Vibration Isolation On the

Ground

Behavior of a Single Molecule-UCLA's

California NanoSystems Institute

Cleanroom Precision Vibration

Isolation

Negative-stiffness vibration

isolation is utilized to provide ultra-stability for multi-disciplined,

nano-level research at UCLA's California NanoSystems

Institute.

NASA/JWST Update: Custom James Webb

Space Telescope Vibration Isolators Working Well

Audiophile Interests: The Doehmann

Helix 1 Turntable

2018 Winners | Minus K Technology

Educational Giveaway to U.S. Colleges and Universities

|

|

|

|