SPIE International Society of Optical Engineering - February 1991

Vibration

Control in Microelectronics, Optics and Metrology

Negative-Stiffness-Mechanism Vibration Isolation

Systems

David L. Platus

Minus K Technology

11775 Gateway Boulevard, #6, Los Angeles, CA 90064 USA

ABSTRACT

A new type of vibration isolation system*

offers significant improvement in performance compared with

current state-of-the-art systems. The system uses negative-stiffness

mechanisms to cancel the stiffness of a spring suspension.

Reduction in stiffness magnifies the damping inherent in

the system creating a practical means for achieving high

hysteretic damping. The result is a simple, compact 6-DOF

passive isolation system capable of system resonant frequencies

below 0.2 Hz and first isolator resonances above 100 Hz.

Resonant transmissibilities below 1.4 can be achieved with

transmissibilities at the higher frequencies close to that

of the ideal undamped system. The negative-stiffness mechanisms

can cancel the stiffness of power cables, hoses or other

lines connected to payloads. This paper develops the theory,

describes typical configurations and summarizes lest data

with prototype systems.

1. THEORY OF OPERATION

1.1 Vertical-motion isolation

A typical vertical-motion isolator uses a conventional spring

to support the payload weight and a negative-stiffness mechanism

(NSM) ("snap-through" or "over-center"

mechanism) to cancel some or all of the stiffness of the

spring, thereby producing low or zero net vertical stiffness.

This approach has been used successfully to simulate zero

gravity in the testing of large space structures (1-2).

Its use in 6-DOF vibration isolation systems as described

in this paper is unique.

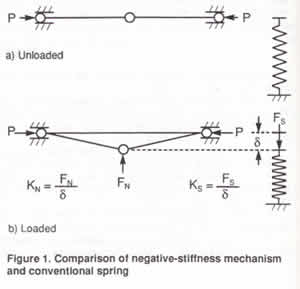

An NSM is illustrated

in Figure 1 and is compared with a conventional spring.

The NSM consists of two bars hinged at the center,

supported at their outer ends on pivots which are

free to move horizontally, and loaded in compression

by opposing forces P. For this example, motions are

constrained to the plane of the paper. In Figure l(a)

the bars arc aligned and arc in a stale of unstable

equilibrium (the center position of the NSM). In Figure

l(b), the center hinge is displaced downward an amount

An NSM is illustrated

in Figure 1 and is compared with a conventional spring.

The NSM consists of two bars hinged at the center,

supported at their outer ends on pivots which are

free to move horizontally, and loaded in compression

by opposing forces P. For this example, motions are

constrained to the plane of the paper. In Figure l(a)

the bars arc aligned and arc in a stale of unstable

equilibrium (the center position of the NSM). In Figure

l(b), the center hinge is displaced downward an amount ![]() and is held in equilibrium by the force FN which opposes the displacement. For small values of

and is held in equilibrium by the force FN which opposes the displacement. For small values of ![]() ,

a linear relationship exits between FN and

,

a linear relationship exits between FN and ![]() which is expressed by the negative stiffness KN.

The behavior of a conventional spring is also shown,

unloaded in Figure l(a) and deflected an amount

which is expressed by the negative stiffness KN.

The behavior of a conventional spring is also shown,

unloaded in Figure l(a) and deflected an amount ![]() by the force FS in Figure l(b).

Here, the force FS acts in the

direction of the displacement

by the force FS in Figure l(b).

Here, the force FS acts in the

direction of the displacement ![]() to hold the deflected spring in equilibrium, and the

ratio of FS to

to hold the deflected spring in equilibrium, and the

ratio of FS to ![]() is the positive stiffness KS.

is the positive stiffness KS.

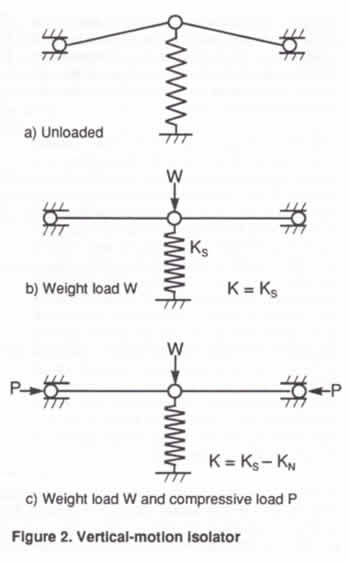

The spring and the NSM are combined to produce the

vertical-motion isolator shown in Figure 2. The isolator

is shown unloaded in Figure 2(a). In Figure 2(b),

a weight load W deflects the spring to the center

position of the isolator. The vertical stiffness of

the system in Figure 2(b) is the spring stiffness.

In Figure 2(c), forces P arc applied to the bars,

creating the NSM which cancels some or all of the

spring stiffness. This is the operating condition

of the system. The resulting isolator stiffness is

K = KN - KS,

and can be made to approach zero while the weight

load is still supported by the spring of stiffness

KS. Flexures can be used in

place of the hinged bars and offer advantages in practical

systems. The compressive load P can be applied by

various means such as a loading screw or a piezoelectric

device.

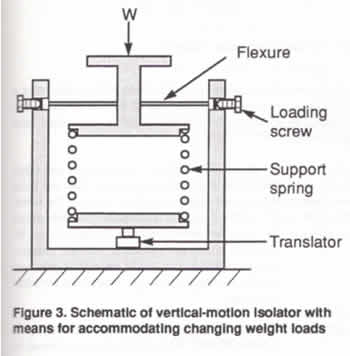

A schematic of a vertical-motion

isolator with means for accommodating changing weight

loads is shown in Figure 3. This isolator uses flexures

and loading screws. A translator raises and lowers

the base of the spring in order to maintain the

center position of the isolator within specified

limits. Automatic leveling can be provided by controlling

the translator with limit switches or with signals

from a displacement transducer.

A schematic of a vertical-motion

isolator with means for accommodating changing weight

loads is shown in Figure 3. This isolator uses flexures

and loading screws. A translator raises and lowers

the base of the spring in order to maintain the

center position of the isolator within specified

limits. Automatic leveling can be provided by controlling

the translator with limit switches or with signals

from a displacement transducer.

1.2 Horizontal-motion isolation

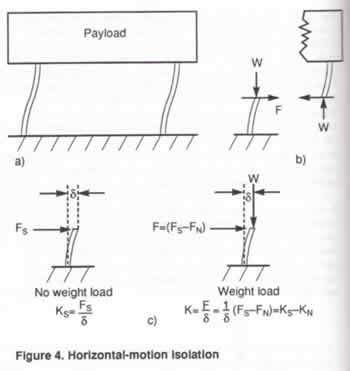

Horizontal-motion isolation can be provided by a

set of flexible columns or beam-columns that behave

as springs combined with NSMs. This is illustrated

in Figure 4 with a planar example in which a payload

is supported on two flexible columns. The displaced

position in response to horizontal excitations is

shown in Figure 4(a). The payload displaces without

significant rotation because the columns are very

stiff in the vertical direction compared with their

stiffness in the horizontal direction. The horizontal

stiffness can be made near zero by designing the

columns to be loaded to approach their critical

buckling loads, thereby producing very low natural

frequencies for horizontal vibrations.

The buckling mode of the system is also generally indicated

by the deformed shape illustrated in Figure 4(a). As the

system collapses, the payload displaces horizontally and

downward. The addition of stops to limit horizontal displacements

produces a system that is fail-safe against collapse due

to inadvertent overload. Limiting the horizontal displacements

of the payload to small values changes the buckling mode

and increases the buckling strength nominally by a factor

of four. Of course, the system does not isolate when the

payload is against the stops.

This approach makes use of the

"beam-column effect," i.e., the reduction

in bending stiffness of a beam-column due to the

axial load. The beam-columns in the isolation system

of Figure 4 are equivalent to two fixed-free columns,

as illustrated in Figure 4(b). Consider the fixed-free

column of Figure 4(c). Without weight load, the

beam-column is simply a cantilever beam with lateral

(horizontal) end load, and acts as a spring with

horizontal stiffness KS. The weight load W produces

bending moments on the laterally-loaded beam, proportional

to the deflection 8. so that less lateral force

is required to produce 8. This behavior is equivalent

to that of a spring of stiffness KS combined with

an NSM having negative stiffness of magnitude KN

that subtracts from the stiffness KS. As W approaches

the critical buckling load, K^ approaches Ks and

the net horizontal stiffness of the beam-column

approaches zero.

This approach makes use of the

"beam-column effect," i.e., the reduction

in bending stiffness of a beam-column due to the

axial load. The beam-columns in the isolation system

of Figure 4 are equivalent to two fixed-free columns,

as illustrated in Figure 4(b). Consider the fixed-free

column of Figure 4(c). Without weight load, the

beam-column is simply a cantilever beam with lateral

(horizontal) end load, and acts as a spring with

horizontal stiffness KS. The weight load W produces

bending moments on the laterally-loaded beam, proportional

to the deflection 8. so that less lateral force

is required to produce 8. This behavior is equivalent

to that of a spring of stiffness KS combined with

an NSM having negative stiffness of magnitude KN

that subtracts from the stiffness KS. As W approaches

the critical buckling load, K^ approaches Ks and

the net horizontal stiffness of the beam-column

approaches zero.

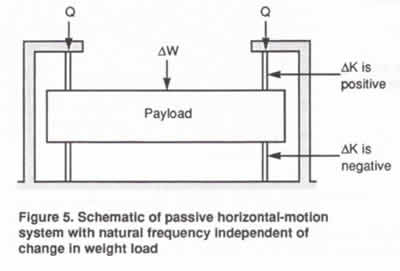

A schematic of a horizontal-motion isolation system

that passively accommodates changing weight loads

while maintaining a fixed isolation system natural

frequency is shown in Figure 5. The payload is supported

on two sets of flexible columns pre-loaded with

axial load Q. Each set has an upper and a lower

column. The lower column supports its part of the

weight load plus the axial pre-load. The upper column

supports only the axial pre-load.

Consider, for example,

the effect of an increase in payload weight. Because

of the axial flexibility of the columns and other

flexibility in the system, the increase in payload

weight increases the axial load on the lower column

and decreases (he axial load on the upper column.

The increase in axial load on the lower column increases

the negative-stiffness effect in the lower column

reducing its horizontal stiffness; the decrease in

axial load on the upper column decreases the negative-stiffness

effect in the upper column increasing its horizontal

stiffness. By proper sizing of the upper and lower

columns, the system can be designed so that the horizontal

stiffness changes in proper proportion to the change

in payload weight so that the natural frequency remains

unchanged.

Consider, for example,

the effect of an increase in payload weight. Because

of the axial flexibility of the columns and other

flexibility in the system, the increase in payload

weight increases the axial load on the lower column

and decreases (he axial load on the upper column.

The increase in axial load on the lower column increases

the negative-stiffness effect in the lower column

reducing its horizontal stiffness; the decrease in

axial load on the upper column decreases the negative-stiffness

effect in the upper column increasing its horizontal

stiffness. By proper sizing of the upper and lower

columns, the system can be designed so that the horizontal

stiffness changes in proper proportion to the change

in payload weight so that the natural frequency remains

unchanged.

Changes in the pre-load Q change the negative-stiffness

effect in the upper and lower columns in the same direction,

thereby providing an independent means for adjusting the

system horizontal stiffness and resonant frequency.

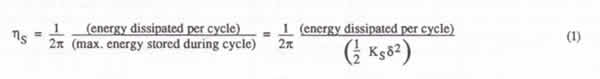

1.3 Damping

Damping is required to limit the isolation system resonant

responses. Reduction in stiffness with the NSM magnifies

the damping inherent in the system, creating a practical

means for achieving high hysteretic damping. High hysteretic

damping is more desirable than high viscous damping because

it can limit resonant responses without significantly reducing

isolation efficiencies at the higher frequencies. This is

illustrated by the transmissibility curves shown in Figure

6 for a hysteretically-damped system. For example, with

a loss factor of 1.0, the resonant transmissibility is 1.4

and the transmissibilities at higher frequencies deviate

only slightly from the ideal undamped curve. For comparison,

a transmissibility curve is shown for a viscously-damped

system that gives the same resonant transmissibility of

1.4 (the viscous critical damping ratio is 0.5). The difference

in transmissibilities between the viscously-damped and the

hysteretically -damped systems at the higher frequencies

is quite dramatic considering the log scale used in the

figure.

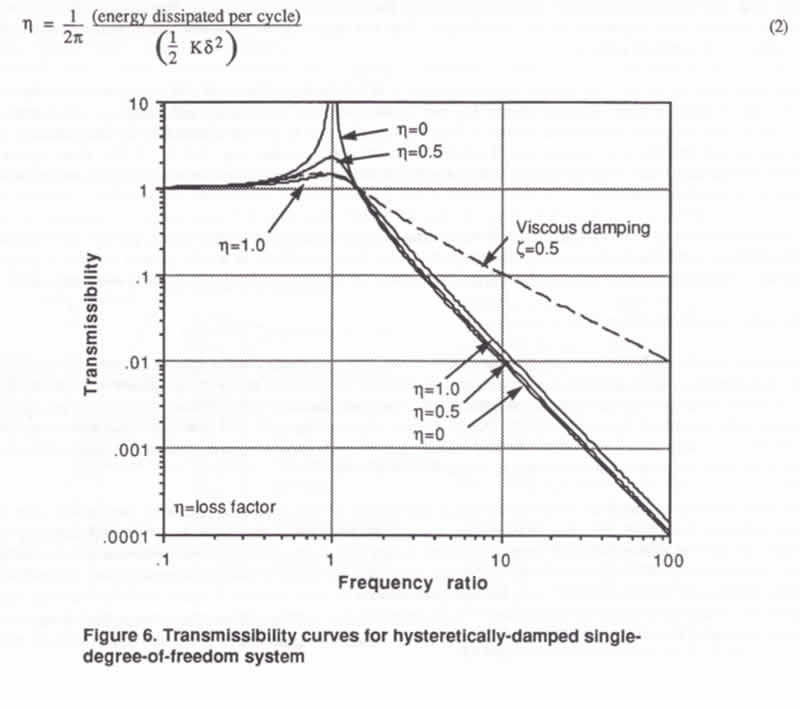

Magnification of the damping by reduction of the stiffness with the NSM can be explained as follows: Consider an ordinary spring with stiffness Kg and loss factor 1)5, supporting a mass and vibrating harmonically with displacement amplitude 5. The loss factor is related to the energy dissipated in the spring and the energy stored in the spring by,

The same basic relationship applies to the isolation system whose stiffness has been reduced from Ks to K by an NSM. The resulting isolation system loss factor is.

As the net stiffness K is reduced by the NSM, the maximum

elastic energy stored during the cycle, and associated

with ![]() ,

is diminished, but the energy dissipated per cycle is

not diminished. The energy dissipated per cycle is the

energy dissipated t" the positive spring, and can

be expressed by Equation (1). Combining Equations (1)

and (2) gives.

,

is diminished, but the energy dissipated per cycle is

not diminished. The energy dissipated per cycle is the

energy dissipated t" the positive spring, and can

be expressed by Equation (1). Combining Equations (1)

and (2) gives.

Thus, the loss factor for the system is the spring loss

factor multiplied by the ratio of spring stiffness to

system net stiffness. It is also equal to the spring loss

factor multiplied by the square of the ratio of system

resonant frequency ![]() s,

based on the spring stiffness, to the system resonant

frequency

s,

based on the spring stiffness, to the system resonant

frequency ![]() based on the reduced stiffness.

based on the reduced stiffness.

A large magnification in damping is possible in a typical

NSM isolation system. For example, consider a system in

which the positive springs alone give a resonant frequency

of 5 Hz (corresponding to Figure 2(b)), and with the NSM,

a resonant frequency of 0.5 Hz. According to Equation

(3) the isolation system loss factor is equal to the spring

loss factor multiplied by 100. For example, one percent

structural damping in the spring would produce 100% structural

damping in the isolation system.

There are benefits from adding damping to the suspension

system, particularly in the form of high-damping viscoelastic

materials. Consider a suspension of steel springs and

a viscoelastic damper. The stiffness of the system is

the sum of the spring stiffness and the damper stiffness,

but essentially all of the damping comes from the viscoelastic

damper. By adding negative stiffness with an NSM equal

in magnitude to the stiffness of the steel springs, the

resulting suspension behaves dynamically as though the

payload were suspended on only the damper. With this approach,

very low resonant frequencies and high damping can be

achieved in compact systems.

The damping behavior of the viscoelastic materials typically

falls between the viscous and the hysteretic curves of

Figure 6. Loss factors for some of these materials exceed

1.0 over certain ranges of temperature and frequency,

and manufacturers are able to tailor their materials to

particular ranges of interest. Materials can be produced

with loss factors exceeding 1.0 at room temperatures and

the low frequencies of interest for vibration isolation,

e.g., 0.2 to 1.5 Hz. Thus, system resonant transmissibilities

lower than 1.4 and transmissibilities at the higher frequencies

close to that of the ideal undamped system can be achieved

in practical systems.

The stiffness of the system can be reduced below that

of the damping material alone, producing system resonant

transmissibilities significantly lower than 1.4. However,

under these conditions in totally passive systems a creep

instability can occur. By retaining some positive stiffness

from the mechanical suspension the system is made inherently

stable.

1.4 Isolation system performance

The performance of real NSM isolation systems that we

have built and tested closely approaches the behavior

shown by the curves of Figure 6 up to frequencies at which

isolator resonances (frequencies at which the isolator

structure itself resonates) occur. Because these isolators

arc simple, compact elastic structures, their isolator

resonances arc readily predictable and can be kept al

high frequencies by proper design. Design studies supported

by tests with prototype isolators indicate that isolator

resonances can be kept above 100 Hz in practical 6-DOF

systems with isolation system resonances (frequencies

at which the system of payload and suspension resonates)

as low as 0.2 Hz or lower.

System resonances in the range of 0.5 to 1.5 Hz are of

interest for a wide range of applications, particularly

with low system resonant response, near-hysteretic-damping

behavior and isolator resonances above 100 Hz. With high-damping

viscoelastic materials currently available, resonant transmissibilities

as low as 1.4 arc achievable with practical passive NSM

isolation systems. Even better performance can be achieved

with automatic centering systems utilizing actuators controlled

by signals from displacement or velocity sensors. Also,

because performance of these isolators is based on deformation

of simple elastic structures and viscoelastic materials,

performance is not degraded (as in conventional pneumatic

isolators) by micro-motions typical of laboratory floors

and fabrication rooms.

2. SYSTEM CONFIGURATIONS

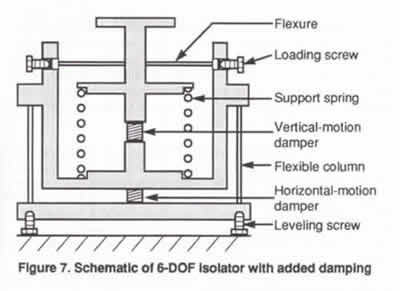

The isolators described above for handling vertical and horizontal vibrations can be combined to produce various configurations of 6-DOF isolators and isolation systems.

2.1 Passive systems

A schematic of a compact passive 6-DOF isolator with

added damping is shown in Figure 7. This isolator

His within a somewhat conventional space, with height

and diameter approximately equal. Design studies indicate

size envelopes for this configuration comparable to

pneumatic isolators that support the same weight loads.

Other configurations depart radically from the conventional

shape, including low-profile configurations that can

optimize the use of limited space in laboratories

and fabrication rooms.

A schematic of a compact passive 6-DOF isolator with

added damping is shown in Figure 7. This isolator

His within a somewhat conventional space, with height

and diameter approximately equal. Design studies indicate

size envelopes for this configuration comparable to

pneumatic isolators that support the same weight loads.

Other configurations depart radically from the conventional

shape, including low-profile configurations that can

optimize the use of limited space in laboratories

and fabrication rooms.

NSM suspension systems are applicable to a very wide

range of weight loads. Added weight is not required

in order to achieve very low resonant frequencies,

nor are the systems limited by very large weights.

For example, very low frequencies can be achieved

with a small isolated platform that supports a microscope

and with systems that support a 3000 lb. photolithography

machine or an entire fabrication room floor.

2.2 Active and automatic leveling systems

An important feature of NSM systems is their capability

for stiffness and frequency adjustment through adjustment

of the NSMs. For example, combining the isolators

of Figures 3 and 5 with a servo system to control

the vertical-motion translator can produce an automatic

leveling system in which the horizontal-motion resonant

frequency is insensitive to changes in payload weight.

By using the servo system to control the vertical-motion

NSM, the vertical-motion resonant frequency can also

be made insensitive to changes in payload weight.

As another example, consider step-and-repeat systems

with stages that arc accelerated and decelerated (photolithography

machines, CMMs, etc.) Feed-forward control systems

can control the NSMs in order to stiffen the system

during stage acceleration and deceleration and soften

the system during exposures or measurements.

An important feature of NSM systems is their capability

for stiffness and frequency adjustment through adjustment

of the NSMs. For example, combining the isolators

of Figures 3 and 5 with a servo system to control

the vertical-motion translator can produce an automatic

leveling system in which the horizontal-motion resonant

frequency is insensitive to changes in payload weight.

By using the servo system to control the vertical-motion

NSM, the vertical-motion resonant frequency can also

be made insensitive to changes in payload weight.

As another example, consider step-and-repeat systems

with stages that arc accelerated and decelerated (photolithography

machines, CMMs, etc.) Feed-forward control systems

can control the NSMs in order to stiffen the system

during stage acceleration and deceleration and soften

the system during exposures or measurements.

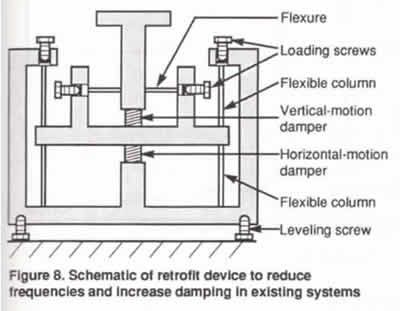

2.3 Retrofit devices

The NSMs described above can be used to retrofit existing

isolation systems in order to reduce system resonant

frequencies and/or to increase system damping. A schematic

of a retrofit device with added damping is illustrated

in Figure 8. A set of devices is connected to the

existing system between the payload and ground without

disturbing the system. Adjustment of the loading screws

adjusts the frequencies and damping to the desired

levels.

3. TEST RESULTS WITH PROTOTYPE SYSTEMS

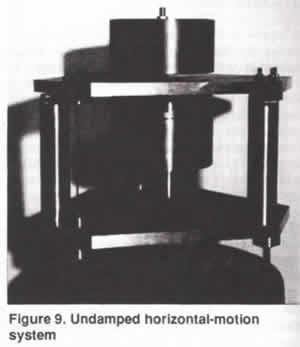

Prototype systems have been built and tested, including

an undamped vertical-motion system and damped and undamped

horizontal-motion systems. An undamped horizontal-motion

system is shown in Figure 9. A small 6-DOF isolated platform

ii being fabricated and will soon be tested.

The undamped

systems demonstrated system resonant frequencies below

0.2 Hz, as determined by visual observations. The

increase in system damping with reduction in system

stiffness was also apparent from observation of the

decay of the free vibrations. Transmissibility tests

were run on some of the horizontal-motion systems.

Typical test data are shown in Figures 10 to 15. The

ideal undamped curves arc shown in Figures 10 and

11 for comparison.

The undamped

systems demonstrated system resonant frequencies below

0.2 Hz, as determined by visual observations. The

increase in system damping with reduction in system

stiffness was also apparent from observation of the

decay of the free vibrations. Transmissibility tests

were run on some of the horizontal-motion systems.

Typical test data are shown in Figures 10 to 15. The

ideal undamped curves arc shown in Figures 10 and

11 for comparison.

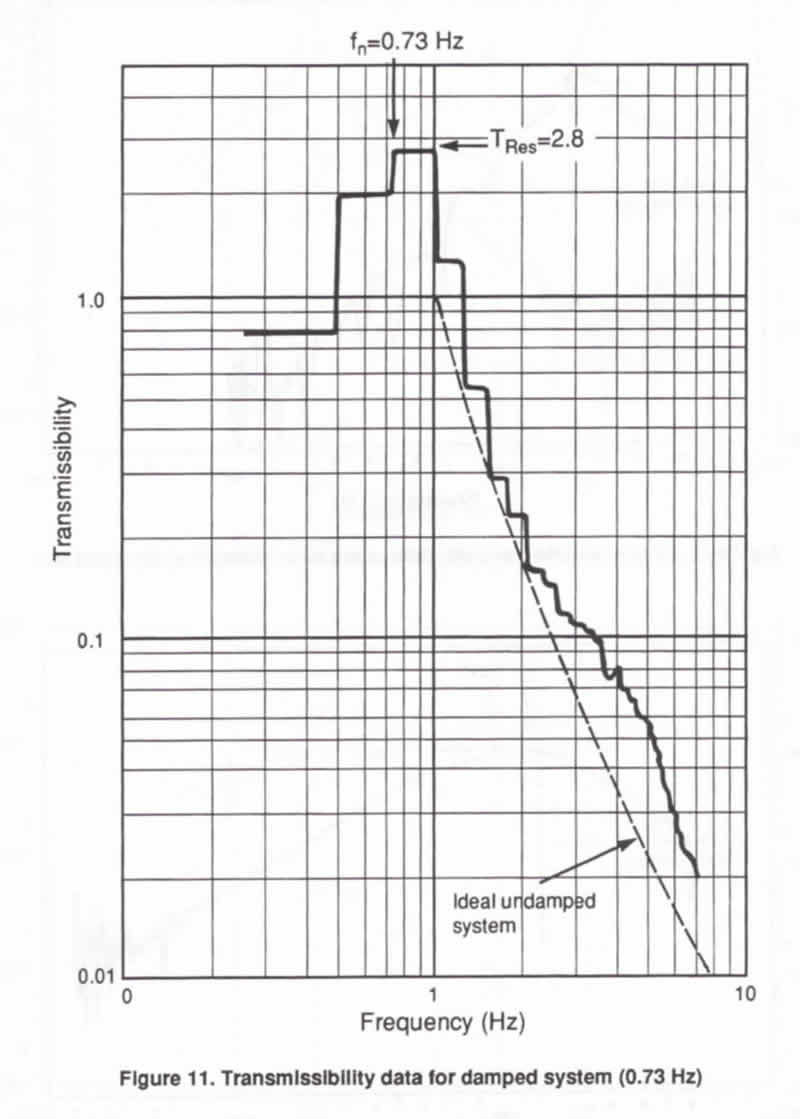

In the damped horizontal-motion systems the payload

is supported on flexible steel columns with viscoelastic

dampers connected in parallel. For the transmissibility

tests, the columns were loaded close to their critical

buckling loads so the systems behaved dynamically

almost as though the payload were supported on only

the dampers. Standard off-the-shelf damping materials

were used which generally arc not optimum for the

room-temperature low-frequency applications of interest.

Optimum formulations of these materials can provide

loss factors exceeding 1.0 and resonant transmissibilities

below 1.4 at low frequencies and room temperatures.

The system of Figure 11 was first tested without the

dampers and tuned to a system resonant frequency of

0.2 Hz. The dampers were then connected, raising the

frequency to 0.73 Hz. Different damping materials

were used for the systems of Figures 10 and 11, neither

of which is optimum from the standpoint of maximum

damping at system resonance.

The transmissibility curves of Figures 10 and 11 were

obtained using forced vibrations from electrodynamic

shakers, v. inputs in the milli-g range. The curves

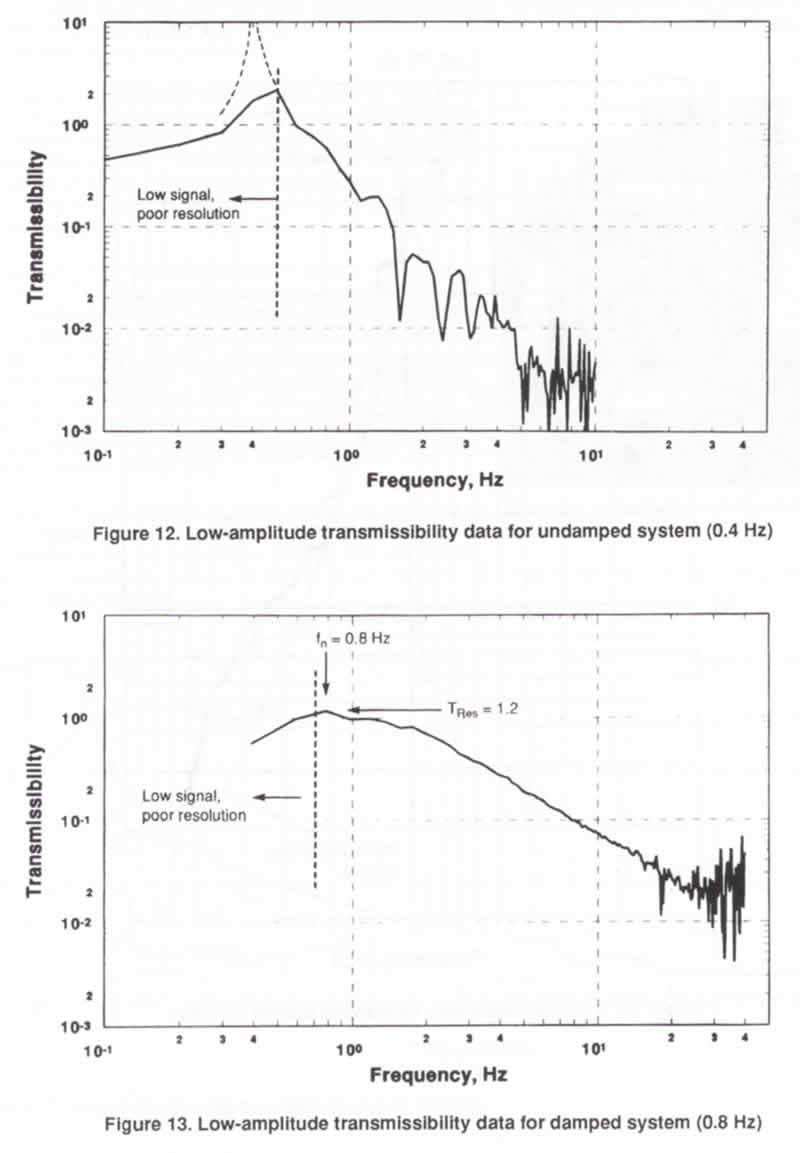

of Figures 12 to 15 were determined from low-amplitude

ambient vibrations laboratory floor with a measured

input of 7.3 x 10* g RMS from DC to 15 Hz. A third damping

material was used for systems of Figures 13 and 15 which

does exhibit loss factors exceeding 1.0 at the system

resonant frequencies. These ambient vibration transmissibility

curves were measured by Dr. R.L. Nigbor of Agbabian

Associates. The method used for these measurements is

described in his paper, "Accurate characterization

of low-level vibration environments using seismological

sensors and systems," also in these proceedings.

The undamped system of Figure 12 has a resonant frequency

around 0.4 Hz. Adding dampers to this system gives the

system of Figure 13 with a resonant frequency of 0.8

Hz and a resonant transmissibility of 1.2. The undamped

system of Figure 14 h_ a resonant frequency of 0.9 Hz.

Adding dampers gives the system of Figure 15 with a

resonant frequency of 4.3 Hz and a resonant transmissibility

of 1.3. For the particular damping material used in

the systems of Figures 13 and 15. transmissibility behavior

is close to the ideal viscous curve shown in Figure

6.

4. SUMMARY OF KEY FEATURES

The following are key features of negative-stiffness-mechanism vibration isolation systems:

-

Passive

-

Compact

-

No air

-

6-DOF isolation

-

Simple automatic leveling for changing weight loads

-

Can provide system resonant frequencies below 0.2 Hz and first isolator resonances above 100 Hz

-

Can provide system resonant transmissibilities below 1.4 with transmissibilities at higher frequencies close to the ideal undamped system

-

Not degraded by micro-motion inputs

-

Can cancel the stiffness of power lines, hoses, cables, etc., connected to payloads

-

Can retrofit existing systems to reduce frequencies and increase damping without disturbing the existing systems

-

Isolation system stiffness can be adjusted manually or automatically

-

Applicable to very small and very large payloads

5. ACKNOWLEDGEMENT

6. REFERENCES

1. R. Ikegami, et. al., "Zero-G Ground Test Simulation

Methods," Proceedings of the 11th Aerospace Testing

Seminar pp. 215-225, The institute of Environmental Sciences,

Manhattan Beach, CA. October 11-13, 1988.

2. S.E. Woodard and J.M. Housner, "Nonlinear Behavior

of a Passive Zero-Spring-Rate Suspension System,"

J Guidance, American Institute of Aeronautics and Astronautics,

Vol. 14, No. 1, pp. 84-89, Jan.-Feb. 1991.

|