SPIE International Society of Optical Engineering - July 1999

Optomechanical

Engineering and Vibration Control

Negative-Stiffness-Mechanism Vibration Isolation

Systems

David L. Platus, Minus K Technology, Inc., 420 S. Hindry

Ave., Unit B, Inglewood, CA 90301

Tel.: 310-348-9656, Fax: 310-348-9638, E-mail: minusk@aol.com

Minus K Technology

11775 Gateway Boulevard, #6, Los Angeles, CA 90064 USA

ABSTRACT

Negative-Stiffness-Mechanism (NSM) vibration

isolation systems offer a unique passive approach for achieving

low vibration environments and isolation against sub-Hertz

vibrations. "Snap-through" or "over-center"

NSM devices are used to reduce the stiffness of elastic

suspensions and create compact six-degree-of-freedom systems

with low natural frequencies. Practical systems with vertical

and horizontal natural frequencies as low as 0.2 to 0.5

Hz provide isolation efficiencies one to two orders of magnitude

better than top-performance air tables and pneumatic isolation

systems. Electro-mechanical auto-adjust mechanisms compensate

for varying weight loads and provide automatic leveling

in multiple-isolator systems, similar to the function of

leveling valves in pneumatic systems. All-metal systems

can be configured which are compatible with high vacuums

and other adverse environments such as high temperatures.

These isolation systems enable vibration-sensitive instruments

such as scanning probe microscopes, micro-hardness testers

and scanning electron microscopes to operate in severe vibration

environments sometimes encountered, for example, on upper

floors of buildings and in clean rooms. Such operation would

not be practical with pneumatic isolation systems. Similarly,

they enable vibration-sensitive instruments to produce better

images and data than those achievable with pneumatic isolators.

The theory of operation of NSM vibration isolation systems

is summarized, some typical systems and applications are

described, and data on measured performance is presented.

KEY WORD LIST

Vibration / Isolation / Isolator / Platform / Suspension

/ Negative-Stiffness / Low-Frequency / Sub-Hertz / Microscopes

/ Micro-hardness.

THEORY OF OPERATION

The theory of NSM isolation systems is

explained in References 1 and 2. It is summarize briefly

for convenience.

Vertical-Motion

Isolation

Vertical-Motion

Isolation

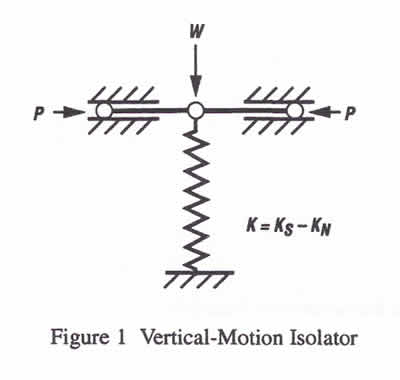

A vertical-motion isolator is shown in Figure 1. It

uses a conventional spring connected to an NSM consisting

of two bars hinged at the center, supported at their

outer ends on pivots, and loaded in compression by

forces P. The spring is compressed by weight W to

the operating position of the isolator, as shown in

Figure 1. The stiffness of the isolator is K=KS-KN where KS is the spring stiffness

and KN is the magnitude of a

negative stiffness which is a function of the length

of the bars and the load P. The isolator stiffness

can be made to approach zero while the spring supports

the weight W.

Horizontal-Motion Isolation

A horizontal-motion isolator consisting of two beam-columns

is illustrated in Figure. 2. Each beam-column behaves

like two fixed-free beam columns loaded axially by

a weight load W. Without the weight load the beam-columns

have horizontal stiffness KS With the weight load

the lateral bending stiffness is reduced by the "beam-column"

effect. This behavior is equivalent to a horizontal

spring combined with an NSM so that the horizontal

stiffness is K=KS-KN, and KN is the magnitude of the

beam-column effect. Horizontal stiffness can be nude

to approach zero by loading the beam-columns to approach

their critical buckling load.

Six-Degree-of-Freedom (six-DOF) Isolation

A six-DOF NSM isolator typically uses three isolators

stacked in series: a tilt-motion isolator on top of

a horizontal-motion isolator on top of a vertical-motion

isolator. Figure 3 shows a schematic of a vibration

isolation system consisting of a weighted platform supported

by a single six-DOF isolator incorporating the isolators

of Figures 1 and 2. Flexures are used in place of the

hinged bars shown in Figure 1. A tilt flexure serves

as the tilt-motion isolator. A vertical-stiffness adjustment

screw is used to adjust the compression force on the

negative-stiffness flexures thereby changing the vertical

stiffness. A vertical load adjustment screw is used

to adjust for varying weight loads by raising or lowering

the base of the support spring to keep the flexures

in their straight, unbent operating position.

Damping

Structural damping inherent in NSM isolators limits the

resonant responses at the natural frequencies. This damping

is magnified by the use of NSMs, as explained in References

1 and 2. The damping magnification can be as high as 100

or greater, limiting the transmissibilities at the natural

frequencies to values below 10. Additional damping is

sometimes provided by the use of elastomeric damping elements,

limiting the transmissibilities at the natural frequencies

to values as low as 2 or 3.

Vertical Auto-Adjustment

One of the shortcomings of low-frequency passive vibration

isolation systems has been their sensitivity to small

changes in weight loads and their susceptibility to large

displacement excursions. This shortcoming has been mitigated

in NSM systems by the use of an electromechanical auto-adjust

mechanism that accommodates variations in weight loads

and maintains the isolators in a precise vertical equilibrium

position. It provides for auto-leveling in multiple-isolator

systems and provides the same function as the leveling

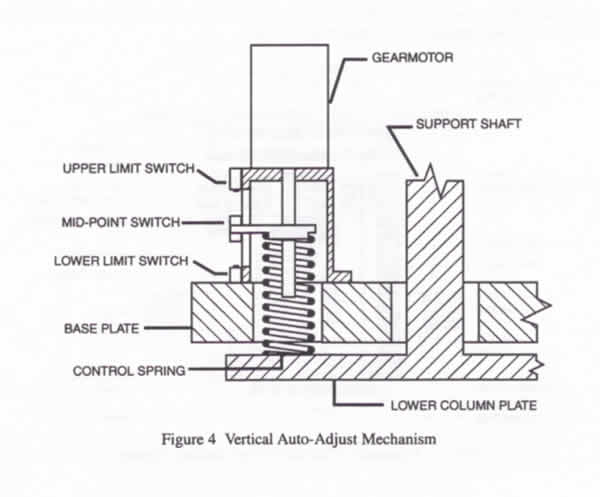

valves in pneumatic vibration isolation systems. A schematic

diagram of an auto-adjust mechanism applicable to the

isolator of Figure 3 is shown in Figure 4, and illustrates

some of the mechanism features.

The auto-adjust mechanism utilizes a pre-compressed control

spring, optical switches (not shown in Figure 4) that

sense changes in vertical position, and a servo-controller.

The control spring adds vertical load to the isolator

by pushing down on the lower column plate. When the vertical

position moves outside a small deadband, the controller

causes a gearmotor to drive a screw that changes the load

on the spring and restores the isolator to its position

within the deadband. A typical load range for the controller

is +/- 2 to 3 Kg to accommodate different specimen weights

in scanning probe microscopes (SPMs) and micro-hardness

testers (MHTs), for example. A manual load-adjustment

screw, such as that illustrated in the isolator of Figure

3, is used to bring the isolator into the range of the

auto-adjust mechanism. A mid-point switch indicates when

the controller is at the middle of its adjustment range

and limit switches indicate when the controller has reached

its adjustment limits.

The buckling mode of the system is also generally indicated by the deformed shape illustrated in Figure 4(a). As the system collapses, the payload displaces horizontally and downward. The addition of stops to limit horizontal displacements produces a system that is fail-safe against collapse due to inadvertent overload. Limiting the horizontal displacements of the payload to small values changes the buckling mode and increases the buckling strength nominally by a factor of four. Of course, the system does not isolate when the payload is against the stops.

TYPICAL APPLICATIONS

Because of their very high isolation efficiencies, NSM vibration

isolation systems enable vibration-sensitive instruments

such as SPMs, MHTs and scanning electron microscopes (SEMs)

to operate in severe vibration environments that would not

be practical with top-performance air tables or other pneumatic

isolation systems.

Figure 5 shows a Nano-K™* "Biscuit" NSM bench

top vibration isolation platform supporting a Digital Instruments

Dimension™ 3000 AFM. The platform is approximately

600 mm square and 200 mm high. Platforms of this type are

capable of supporting payloads up to 160 Kg or more. Figure

6 shows the Digital Instruments IS3K Hood used with the

Dimension™ 3100 AFM, which includes an acoustic shield

and a custom Nano-K™ "Biscuit" NSM isolator.

This hood allows the Dimension™ 3100 AFM to produce

measurements at the nanometer (lateral) and sub-Angstrom

(vertical) scales in noisy acoustic and vibration environments.

An NSM vibration isolation floor platform for a SEM is shown

in Figure 7. The platform uses three Nano-K™ 1000SM-1

isolators of the type shown schematically in Figure 3, each

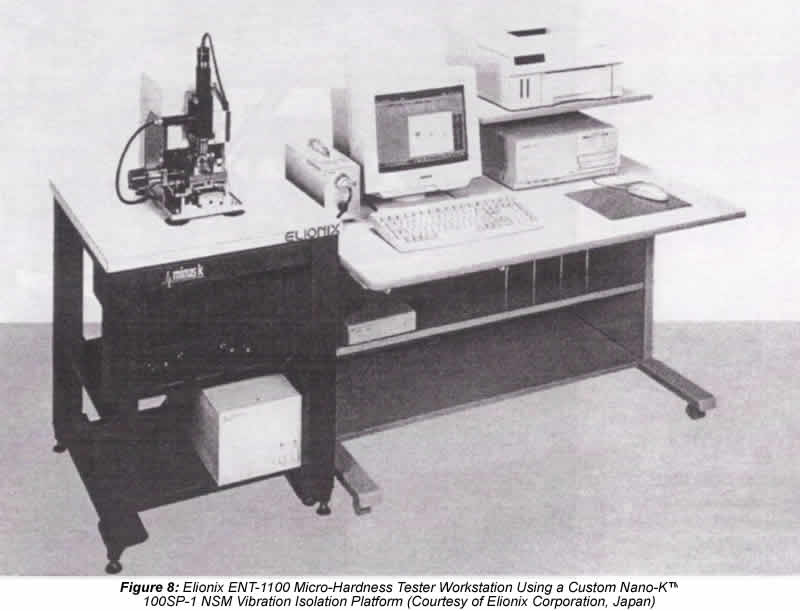

with a payload capacity of about 450 Kg. Figure 8 shows

a workstation for an Elionix ENT-1100 Micro-Hardness Tester

using a custom Nano-K™ 100SP-1 NSM single-isolator

platform of the type shown schematically in Figure 3.

All-metal NSM vibration isolation systems can be configured

which are compatible with high vacuums and other adverse

environments such as high temperatures. Small NSM platforms

similar to that shown schematically in Figure 3, and measuring

about 100 mm high and 150 mm in diameter, have been used

to support scanning tunneling microscopes in ultra-high

vacuums. These platforms have demonstrated vertical and

horizontal natural frequencies as low as 0.5 Hz.

PERFORMANCE

Transmissibility Data

The behavior of NSM vibration isolation systems approximates that of six-DOF linear spring systems up to about 10 to 20 Hz. That is. isolation starts at a frequency of 1.4 times the natural frequency and rolls off at about 12 dB per octave with increasing frequency of the input vibrations. Above 10 to 20 Hz the transmissibility tends toward a constant "floor" value until internal structural resonances are reached. For 0.5-Hz systems this "floor" value is approximately -55 to -60 dB, The internal structural resonances in practical systems can be kept above 70 to 80 Hz or higher, while the system natural frequencies can be kept low. The natural frequencies of NSM isolation systems of the type shown in Figures 5 to 8 can be adjusted, typically, to 0.5 Hz or lower, vertically and horizontally. Some of them can be adjusted to frequencies as low as 0.2 to 0.3 Hz.

Figure 9 shows transmissibility data for a Nano-K™

100SP-1 single-isolator NSM platform of the type shown

schematically in Figure 3, with a natural frequency of

approximately 0.5 Hz. It indicates transmissibilities

of approximately -20 dB at 2 Hz. -40 dB at 5 Hz and -50

dB at 10 Hz.

Comparison of MHT Data Using NSM and Pneumatic Vibration Isolation Systems

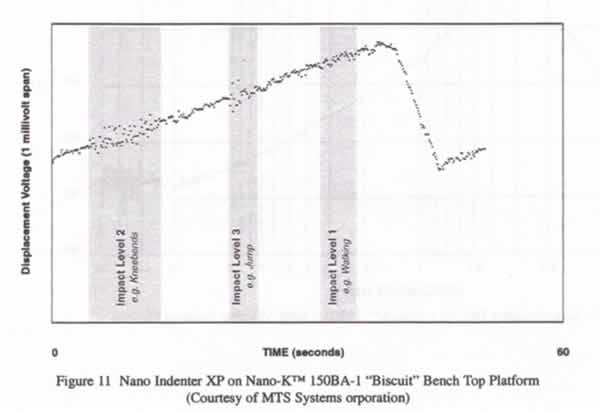

Vibration response of a Nano Indenter XP manufactured by MTS Systems Corporation was compared on an NSM bench top vibration isolation platform and on a on a high-performance air table for severe vibrations produced by impacting the floor. The indenter was set up in a way to maximize its sensitivity to external vibrations. The data are shown in Figures 10 and 11 in terms of displacement voltage vs time.

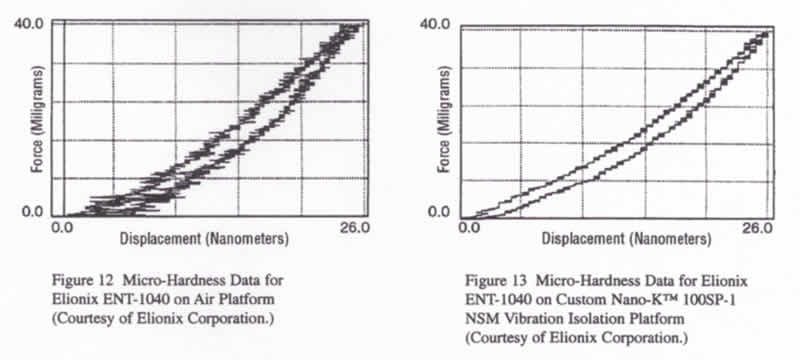

Micro-hardness data for Silicon taken on an Elionix ENT-1040 Ultra Micro-Hardness Tester supported on an air platform and on an NSM platform is shown in Figures 12 and 13.

Based on field test data. NSM vibration isolation systems such as those shown in Figures 5 and 6 typically reduce the vibration noise levels in AFMs by a factor of 2 to 3 or more when compared with top-performance air tables. This is particularly significant for noise levels in the sub-Angstrom range. The use of NSM vibration isolation systems result in clearer images and features not discernable with pneumatic isolation systems. They also enable AFMs to be used in severe environments that would not be practical with pneumatic isolators.

REFERENCES

1. Platus. D. L. "Smoothing out Bad Vibes."

Machine Design. February 26. 1993. p. 123.

2. Platus. D. L.. "Negative-Stiffness-Mechanism

Vibration Isolation Systems. SPIE Vol. 1619 Vibration

Control in Microelectronics. Optics, and Metrology (1991)

pp. 44-54.